Time:2025-12-06Reading:1215Second

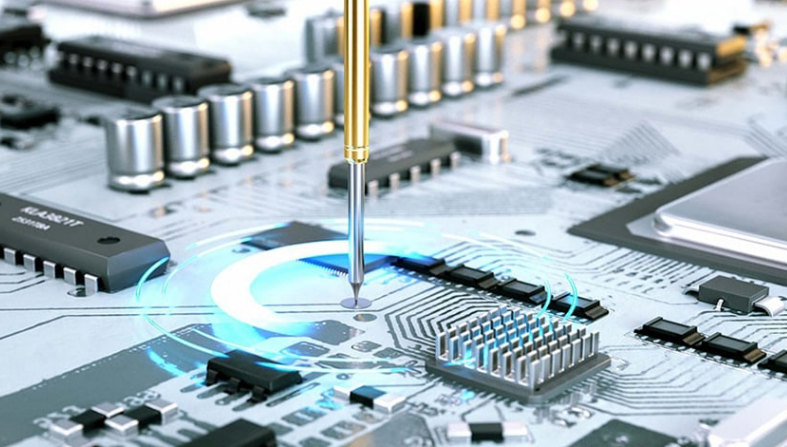

Radio frequency test needle is a key testing tool used for signal detection, transmission, and measurement in the radio frequency (RF) and microwave frequency range. It is mainly used for signal insertion, detection, and measurement output of high-frequency RF, RF, and microwave modules, as well as electrical performance analysis of high-frequency circuit boards. It is a fundamental tool for ensuring the performance and reliability of high-frequency electronic equipment.

The working logic of the RF test needle is based on the theory of electromagnetic coupling and transmission lines, with the core of achieving "low interference, low loss" signal transmission. The key technical points include:

Signal access and extraction:In high-frequency circuits, low loss access to RF signals is achieved by contacting the tested device (such as chip pads, circuit board microstrip lines) with tiny probe tips, extracting voltage, current, or electromagnetic field information from the circuit.

Impedance matching:The probe design must strictly match the characteristic impedance of the tested circuit, minimize signal reflection and loss, and ensure signal transmission efficiency and measurement accuracy.

Anti interference design:By using shielding structures, grounding treatments, and selecting low dielectric loss materials, external electromagnetic interference and crosstalk are suppressed to ensure the stability of weak signal detection.

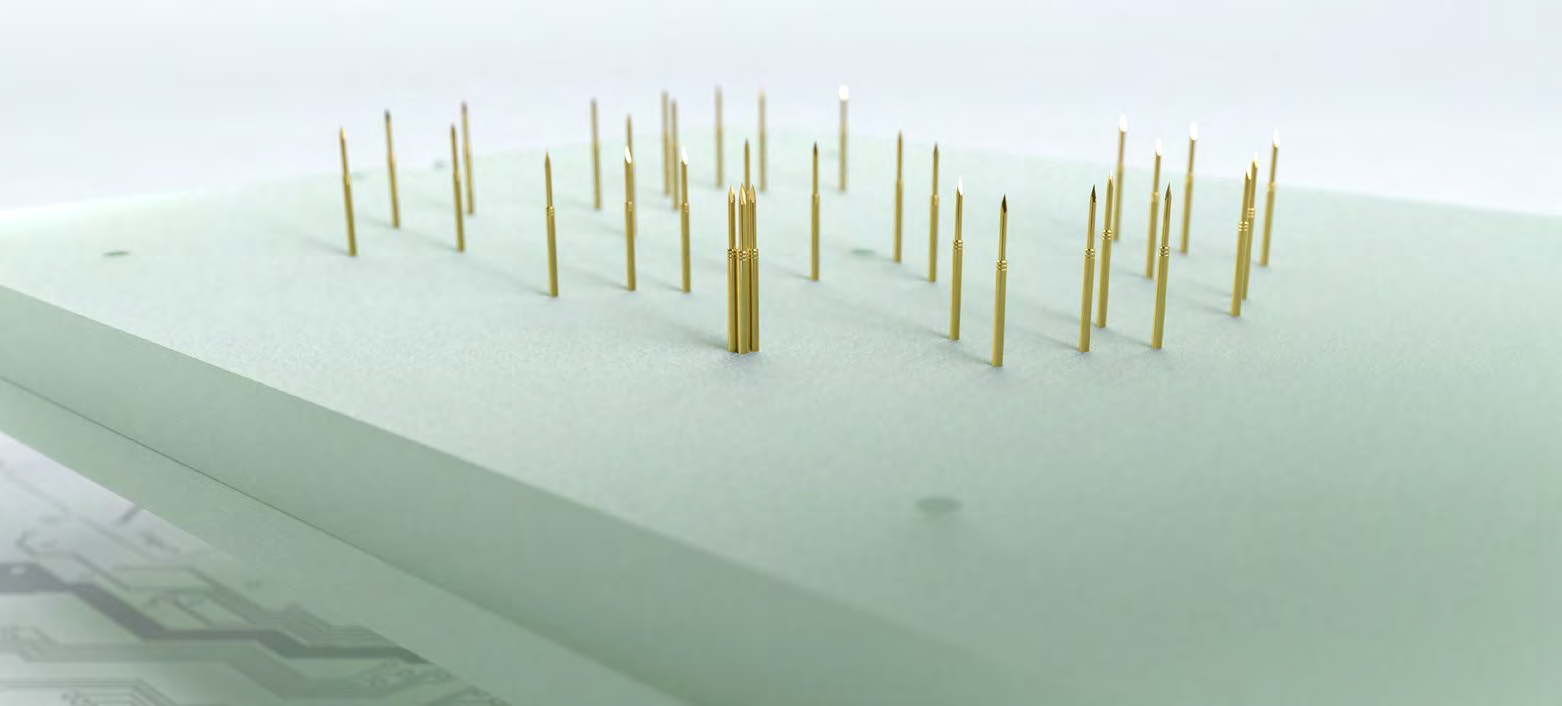

Generally, test points with different spacing on PCBs are paired and used on an automated robotic arm inside the chassis.

Peel off the core wires of a pair of rigid cables and install them inside the same fixture. Bend the cables at the contact ends to a fixed spacing and manually test them.

Used for testing in the semiconductor industry, optoelectronic industry, integrated circuits, and packaging, with high precision and testing frequency.

A pogo pin is a structure composed of three basic components: a needle shaft, a spring, and a needle tube. The probe as a whole has a certain stroke and elasticity.

Functional verification and debugging:RF needles are widely used in the functional verification and debugging process of integrated circuits, which measure internal RF signals by directly contacting the electrodes or pads of the chip.

Parameter extraction:During the new product development phase, RF needles can be used to measure the true characteristics of RF components at the chip level, helping engineers extract key performance parameters.

Design verification:In the design verification phase, the RF needle helps confirm whether the circuit design meets the expected RF performance requirements, avoiding large-scale problems in the later stage.

RF component testing:RF needles are used to test and evaluate the performance of RF components on printed circuit boards, such as filters, amplifiers, and antennas, to ensure their normal operation at different frequencies.

Signal integrity measurement:RF needles can measure the signal integrity on PCBs, including insertion loss, return loss, and transmission loss parameters, to ensure the stability and reliability of signal transmission.

RF performance testing:RF needles are widely used for RF performance testing of wireless devices such as mobile phones, base stations, and wireless routers, analyzing the transmission and reception performance of the equipment to ensure compliance with industry standards.

EMI/EMC testing:In electromagnetic compatibility (EMC) and electromagnetic interference (EMI) testing, radio frequency needles help identify and suppress electromagnetic interference sources, improving the anti-interference ability of equipment.

Radar system testing:The radio frequency probe is used for testing the automotive radar system to ensure the stable operation of the radar sensor in various environments and improve the safety and reliability of the auto drive system.

Wireless communication module testing:RF needles can also be used to test the performance of wireless communication modules in cars, such as Wi Fi, Bluetooth, and 5G modules, to ensure the stability and safety of in car communication.

High frequency and broadband:With the development of 5G/6G, millimeter wave radar, and terahertz technology, probes need to break through higher frequency limitations;

Intelligence and automation:Combining AI algorithms to achieve automatic calibration of contact force, monitoring of needle tip wear, and intelligent diagnosis of testing faults, reducing manual intervention;

The performance of RF needles directly affects the accuracy of test data. The machining accuracy and material selection of their core components (such as needle tips, springs, etc.) are crucial, and the industry mainly focuses on customized needs. Therefore, it is particularly important to choose original manufacturers with the following capabilities:

Full process independent production capability:After the raw materials are received, they undergo turning processing, cleaning, heat treatment, electroplating, assembly, inspection and shipment to achieve full process self control and ensure quality consistency;

Customized R&D strength:Capable of customizing based on drawings and samples, or designing and developing probes for special application scenarios;

Standardized quality control system:Establish a comprehensive inspection process through ISO quality management system certification.

As a national high-tech enterprise with over 40 years of "fully self operated and large-scale" probe production lines, Centalic focuses on the research and manufacturing of various testing probes. Covering the entire process from raw material processing to finished product shipment, we strictly control delivery time and quality through standardized production processes, which can meet the customized testing needs of different industries.

In the future, with the continuous advancement of technologies such as 5G, 6G, quantum computing, and advanced semiconductor packaging, RF needles will iterate towards the direction of "higher frequency, smaller needle spacing, and multi-channel integration", becoming the core foundational tool supporting innovation and high-quality development of the high-frequency electronics industry.