Time:2026-01-23Reading:808Second

In the electronic manufacturing industry, ICT testing needles are key to ensuring product quality and performance. As the core component of ICT testing fixtures, the performance of test needles directly affects the accuracy and efficiency of test results. Therefore, choosing high-performance ICT testing needles is crucial. The following is a detailed introduction on how to choose high-performance ICT test needles, aimed at providing readers with comprehensive and in-depth guidance.

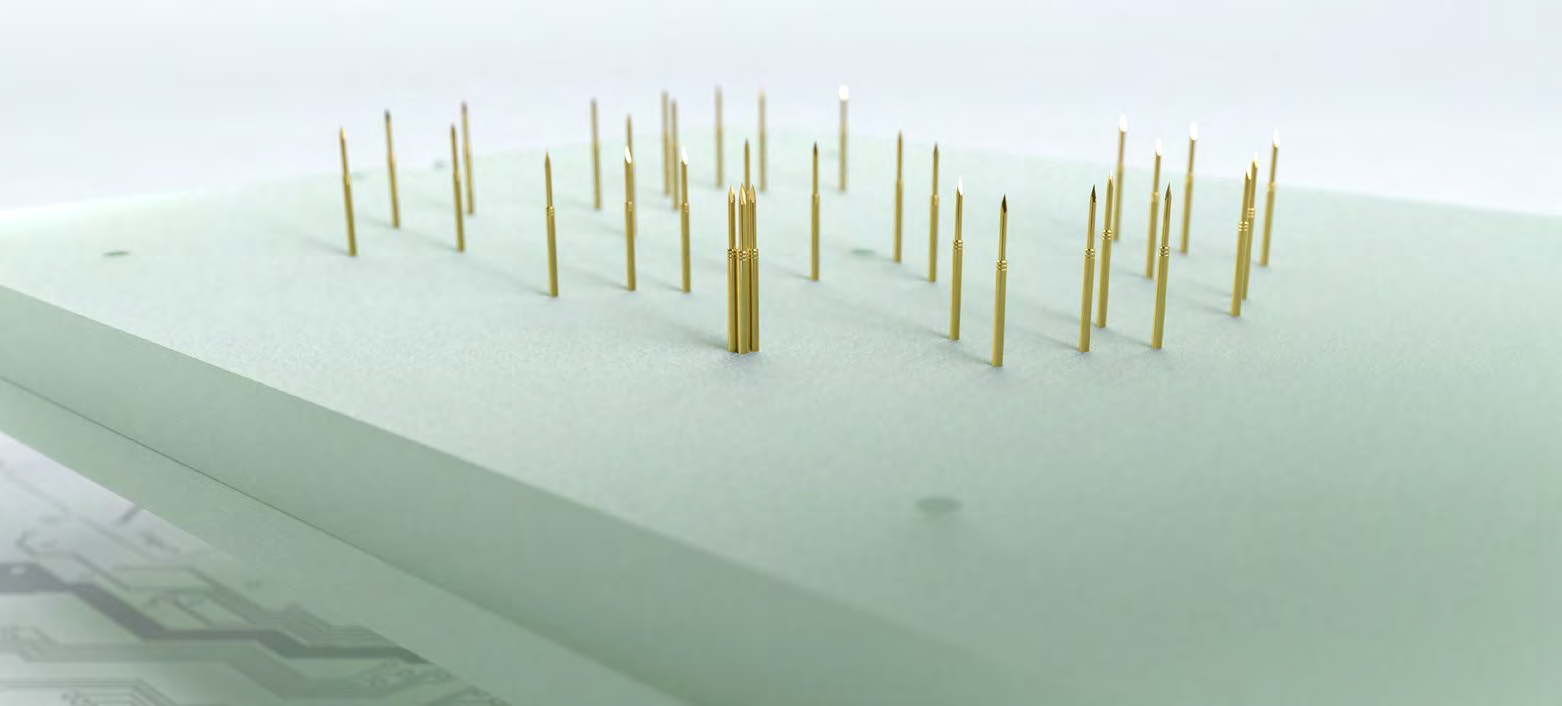

ICT testing needle, also known as ICT online testing needle or spring needle, is a precision electronic component. Its core structure consists of three parts:

syringe needle:Directly contact the critical parts of the tested device. The selection of its head shape will directly affect the effectiveness of the test.

Spring:Provide necessary contact force to ensure stable contact between the test needle and the test point.

Needle tube:As a supporting structure, it protects the internal springs and transmits signals.

ICT testing needles are mainly used for online circuit testing and functional testing, detecting the electrical performance of online components on the board and the connection status of the circuit network. They can quantitatively measure and perform functional testing on the components.

Usually, ICT online testing needles are used together with their matching size needle sleeves, which are fixed on the PCB board for easy replacement of probes at any time.

(1) Material and Coating

Material:Prioritize the use of high-quality substrates with excellent conductivity and high-strength wear-resistant properties. This type of material can effectively withstand the friction loss of high-frequency reciprocating testing, maintain stable testing accuracy, and fundamentally avoid problems such as poor contact caused by insufficient material adaptation.

Coating:The selection of coating is crucial for the wear resistance and corrosion resistance of the test needle. High quality coatings can significantly improve the service life of test needles and reduce testing errors caused by wear or corrosion. Common coating materials include gold, nickel, etc.

(2) Spring and elasticity

弹簧:The spring is a key component that provides contact force for the test needle. High quality springs should have good elastic recovery and stability to ensure stable contact force even after long-term use.

Elasticity:The greater the elasticity, the better. The selection of elasticity should be based on the actual situation of the test point. Insufficient elasticity may lead to poor contact, while excessive elasticity may damage the test point.

(3) Size and accuracy

Diameter and spacing:The diameter of the test needle should be selected based on the spacing and size of the test points. The closer the test points on the PCB board are, the thinner the outer diameter of the selected test pins should be to ensure testing accuracy and avoid short circuits.

Accuracy:The diameter accuracy of the casing has a significant impact on the overall accuracy of the testing fixture. High precision tubing can ensure that the test needle maintains a stable trajectory and contact position during movement, thereby improving the accuracy of test results.

(4) Electrical characteristics

Contact resistance:Require extremely low and long-term stability with minimal fluctuations to ensure measurement accuracy.

Current carrying capacity:It is necessary to meet the requirements of the testing plan, such as the need for probes that can carry several amperes of current for power short circuit testing.

There are a variety of ICT testing needle brands in the market, with significant differences in price and quality. When purchasing, it is necessary to avoid traps such as "low price, poor quality, and no after-sales service", and prioritize choosing manufacturers with core strength and a complete service system. You can filter from the following three dimensions:

Priority should be given to manufacturers with independent research and development capabilities and their own factories. This type of manufacturer can deeply understand complex testing scenarios, provide customized solutions, and control quality and delivery from the source. For example, Suntory has been focusing on probe research and production for more than 40 years. As a national high-tech enterprise, it has a fully self operated large-scale production line, achieving integrated control of research, production, and sales. It can provide probe products covering more than 30000 specifications, and can also provide customers with one-stop testing solutions and customized services to adapt to various high-precision and high demand testing scenarios.

Be wary of "no brand, no parameters, and no after-sales service" products. Although these products are cheap, their contact resistance is unstable and their lifespan is short, which can easily lead to testing errors, damage to the tested parts, and increase overall costs. When purchasing, a full lifecycle cost accounting mindset should be established, taking into account factors such as probe prices, replacement frequency, maintenance costs, and testing misjudgment losses, rather than simply comparing individual prices.

During the selection and debugging process of ICT testing needles, it is often necessary to adapt to non-standard fixtures and special testing scenarios, and a comprehensive service system is crucial. Prioritize selecting probe manufacturers that can provide after-sales and on-site technical support to assist customers in optimizing testing plans.