Time:2026-01-09Reading:905Second

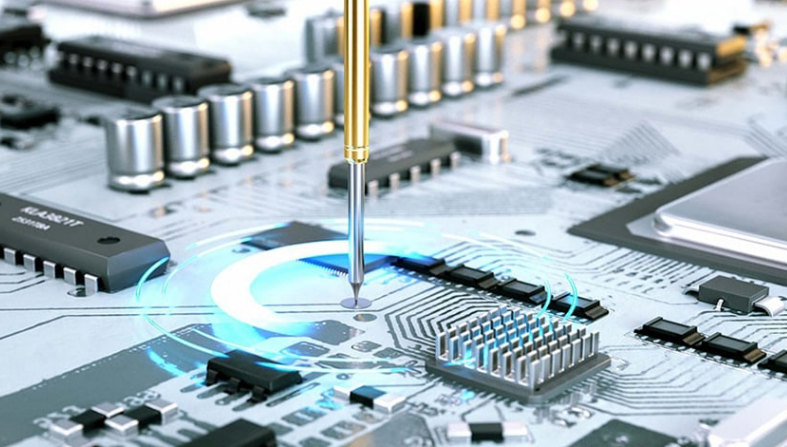

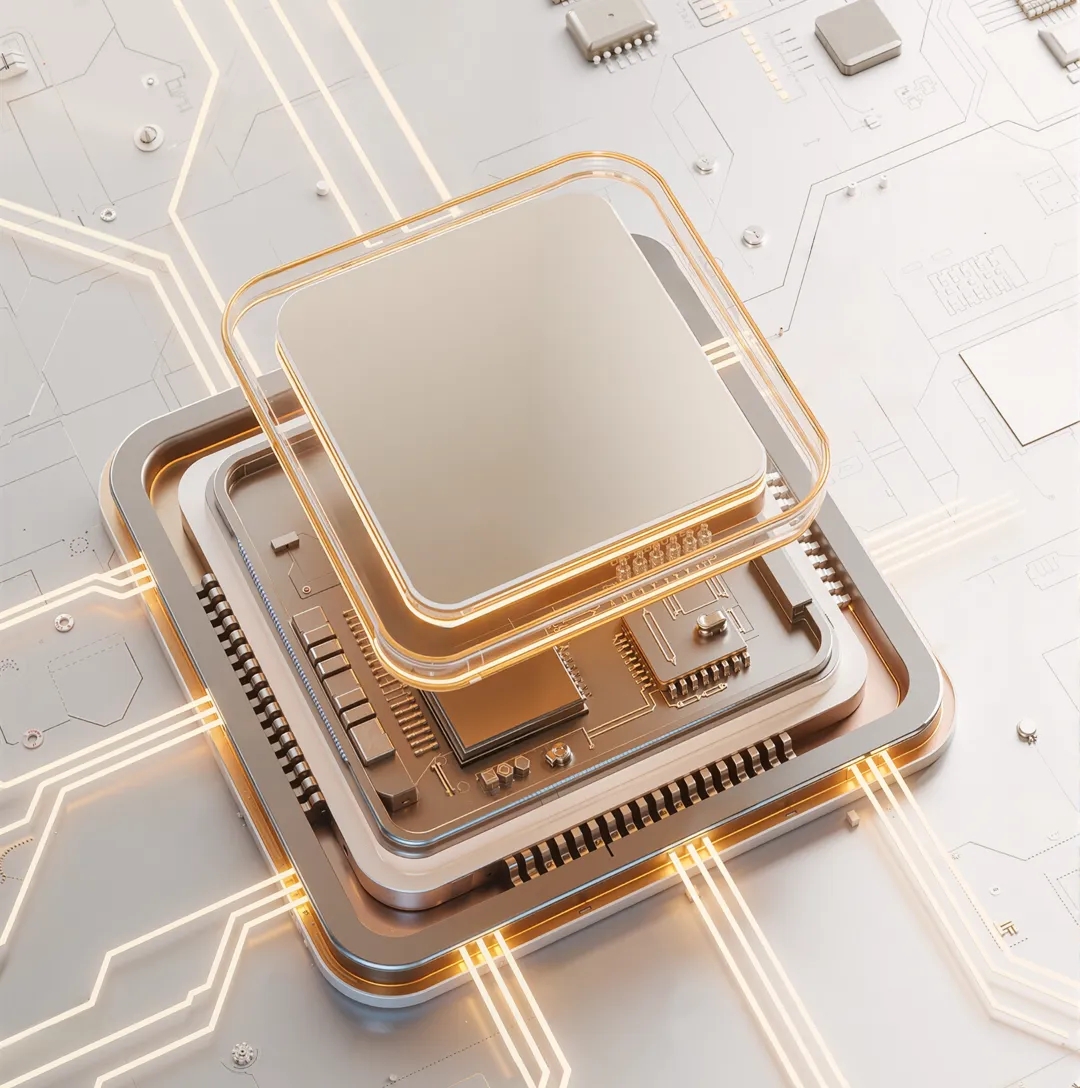

In chip manufacturing, equipment such as lithography machines and etching machines are often the main focus of attention. However, at the nanoscale, there is an invisible 'hand' that runs through the entire process of chip creation - it is the semiconductor probe. It is these precise metal contacts, like the most rigorous quality inspectors, that safeguard the reliability of every chip from silicon wafers to products.

1、 Probe essence: a "signal bridge" connecting micro and macro levels

Semiconductor probes are high-end precision electronic components whose core mission is to establish stable and reliable electrical connections between tiny solder joints on chips and testing equipment, achieving precise transmission of testing signals.

In chip testing, the test probe may seem small, but it is an indispensable core consumable in the testing process - it connects one end to the chip pin (or wafer solder ball) and the other end to the testing machine. Through precise transmission of electrical signals, it detects the conductivity, current stability, functional integrity, and even aging performance of the chip in high temperature environments.

2、 Guarding process: "Dual physical examination" before chip mass production

The value of probes is concentrated in two key stages of chip testing:

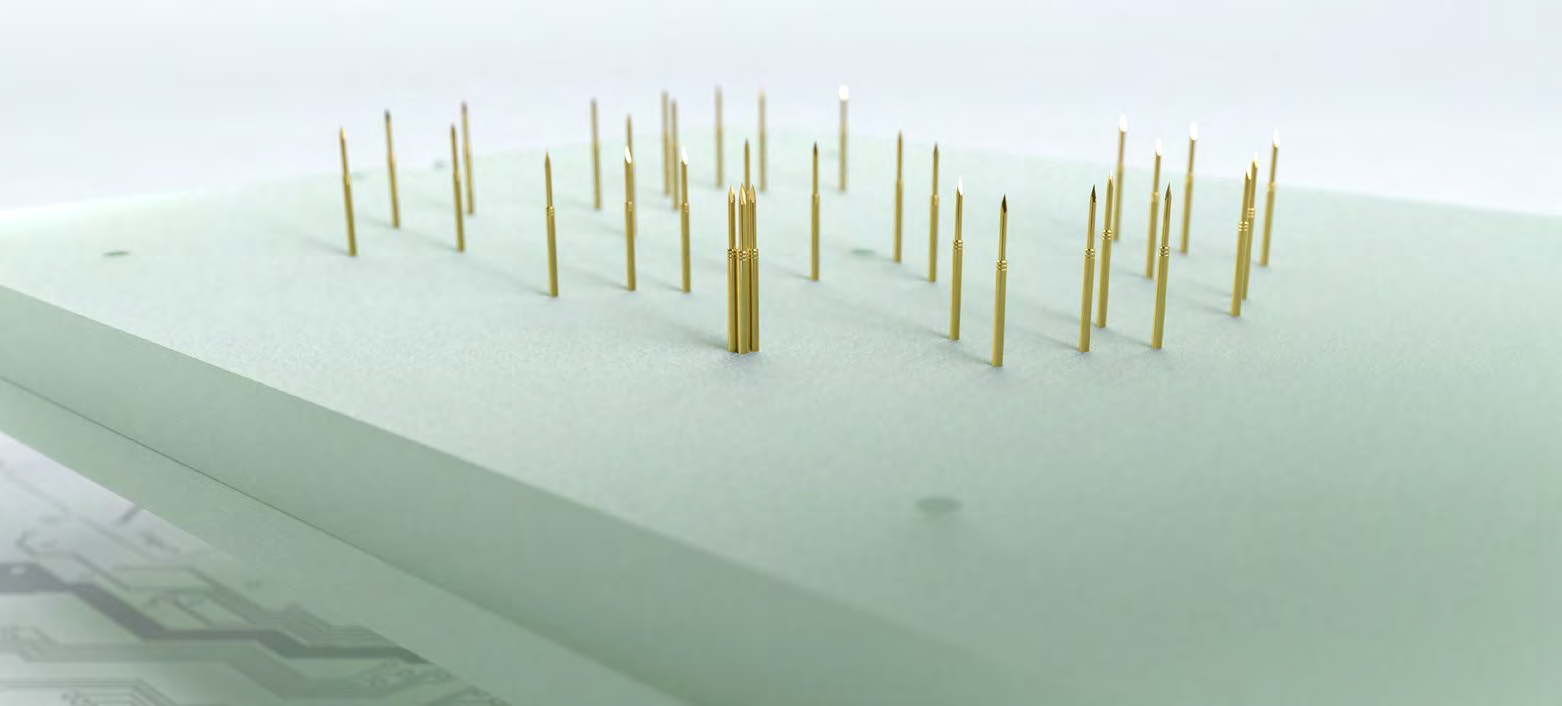

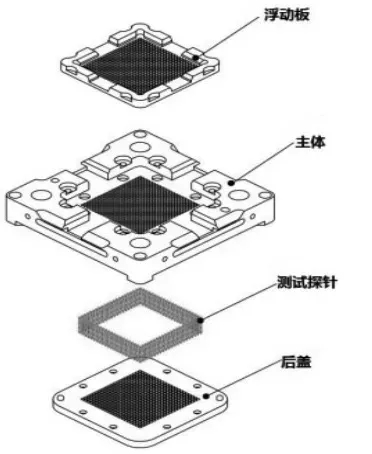

Wafer testing (CP testing):Before chip cutting and packaging, a "probe card" equipped with hundreds to thousands of probes simultaneously conducts contact testing on the entire chip on the wafer. This stage is like "prenatal screening", quickly screening out defective products to avoid them flowing into high cost packaging processes, which directly affects manufacturing costs and efficiency.

Final Test (FT Test):After the chip is packaged, the probe conducts comprehensive functional and performance verification of individual chips in the testing socket. This is the 'final physical examination' before delivery to ensure that each factory chip meets the design specifications and can work stably in real applications.

A high-end chip needs to undergo thousands of probe contacts, therefore, the accuracy, stability, and durability of the probe itself directly determine the accuracy of testing yield and the final quality of the product.

![]()

3、 Development Pattern: From Global Competition to the Rise of Chinese Power

The global probe technology market is fiercely competitive and has long been dominated by companies from countries such as the United States, Japan, and South Korea. These enterprises maintain a leading position in the market by virtue of their profound accumulation in precision manufacturing and materials science.

It is worth noting that in recent years, Chinese companies have achieved leapfrog development in the field of probe technology. Through continuous R&D investment and tackling core process challenges, we have not only narrowed the gap with international leading levels, but also achieved a leap from following to running in some segmented fields, injecting new vitality into the global market.

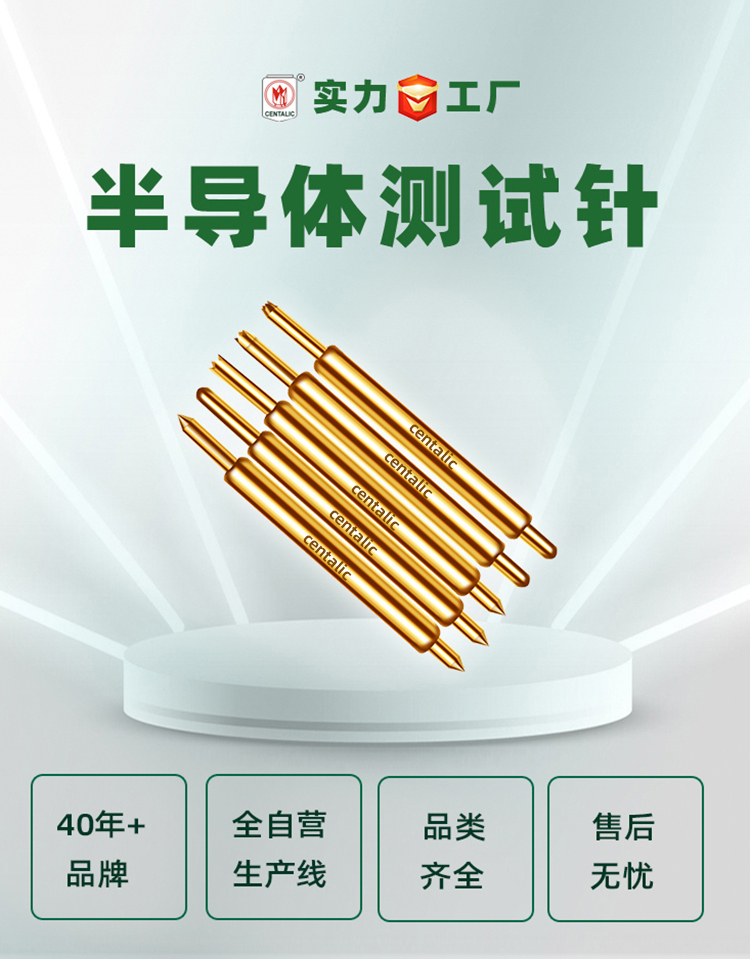

As a national high-tech enterprise with over 40 years of experience in probe research and development and manufacturing, Suntory has established a full chain capability from R&D design, large-scale production to customized services, providing domestic and foreign customers with multi scenario testing solutions including high-frequency, high current, micro spacing, etc., meeting their R&D and mass production needs.

4、 Future development direction of probes

High density and small spacing testing requirements:As chip processes evolve towards 2nm and more advanced nodes, probe technology also faces new challenges.

High frequency testing capability:Meet the testing requirements of high-frequency application scenarios such as 5G/6G.

Despite their small size, test probes play an irreplaceable role in various aspects of chip manufacturing. It not only ensures the quality of chip products, but also promotes technological progress in the entire semiconductor industry.

Looking ahead to the future, with continuous technological innovation, testing probes will develop towards higher precision and stronger performance, providing more solid technical support for the digitalization process of humanity.