Time:2025-12-20Reading:1057Second

The testing industry covers a wide range of fields, with different scenarios corresponding to different 'combat needs'.For this reason, the testing probe family has spawned multiple "sects", each with their own specialties and responsibilities:

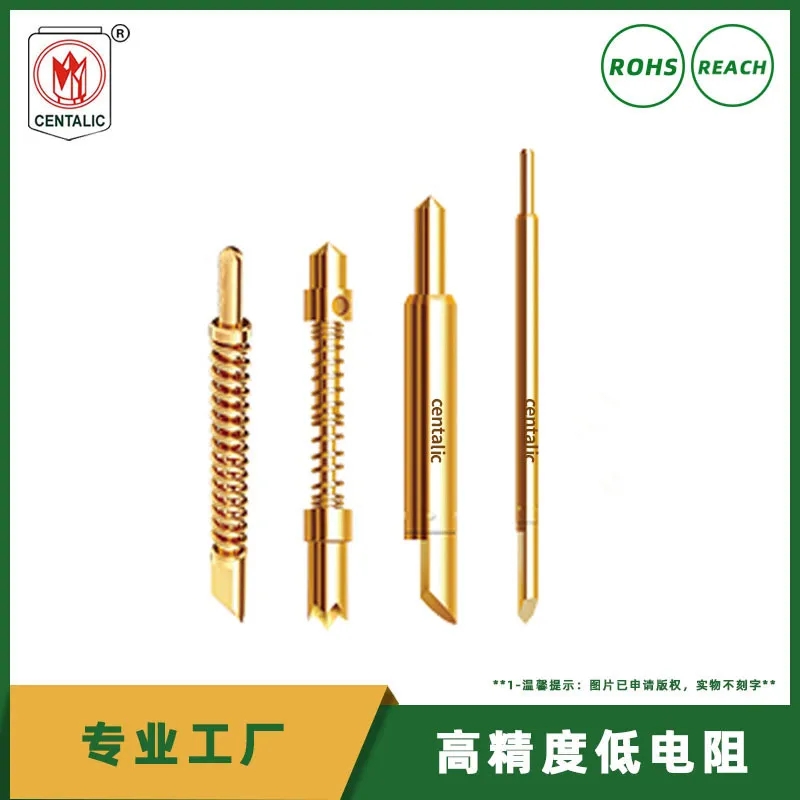

1. Semiconductor probes - series:

Mainly used for various communication power electronic components, semiconductor wafer testing, chip packaging testing, etc., with extremely low contact resistance and ultra-high bandwidth, it can meet the requirements of 5-40G high-frequency signal testing. At present, Centalic can process the minimum probe diameter: needle diameter: 0.06mm/needle tube diameter: 0.10mm.

2. High current probes - series:

Mainly used in the field of online testing for high temperature and high current. Its characteristics are high testing current and high testing temperature conditions.

3. ICT Probe Series:

Mainly used for online circuit testing and functional testing, detecting the electrical performance of online components on the board and the connection status of the circuit network, and being able to quantitatively measure and perform functional testing on the components. Usually, ICT online testing needles are used together with their matching size needle sleeves, which are fixed on the PCB board for easy replacement of probes at any time.

4. Kelvin Probe Series:

Mainly used in the field of resistance testing, it is suitable for testing electronic components with small and low resistance values.

5. RF Probe - Series:

Mainly used for signal insertion, detection, and measurement output of high-frequency RF, RF, and microwave modules, as well as electrical performance analysis of high-frequency circuit boards. Having the characteristics of relatively concentrated signals that can pass through and low loss, there are very high requirements for the impedance and loss of RF probes in the testing of high-speed digital circuit boards and microwave chips. The design structure of RF probes is complex, with multiple components and high added value, and they are mostly customized.

6. Bullet Probe - Series:

Mainly used for testing precision spacing connectors such as mobile phones, chips, screens, etc. It has the characteristics of being able to handle smaller pitches, high testing efficiency, high stability, and long lifespan, and plays a role in transmitting signals and conducting currents.

7. Non magnetic probes - series:

Made of non-magnetic materials, mainly used for areas that are difficult for inspectors to directly inspect. It can meet the testing requirements in special non-magnetic environments, such as the inspection of medical devices, underground or stored goods, and improve the safety factor during inspections in dangerous and difficult environments. It has been widely applied in multiple fields.

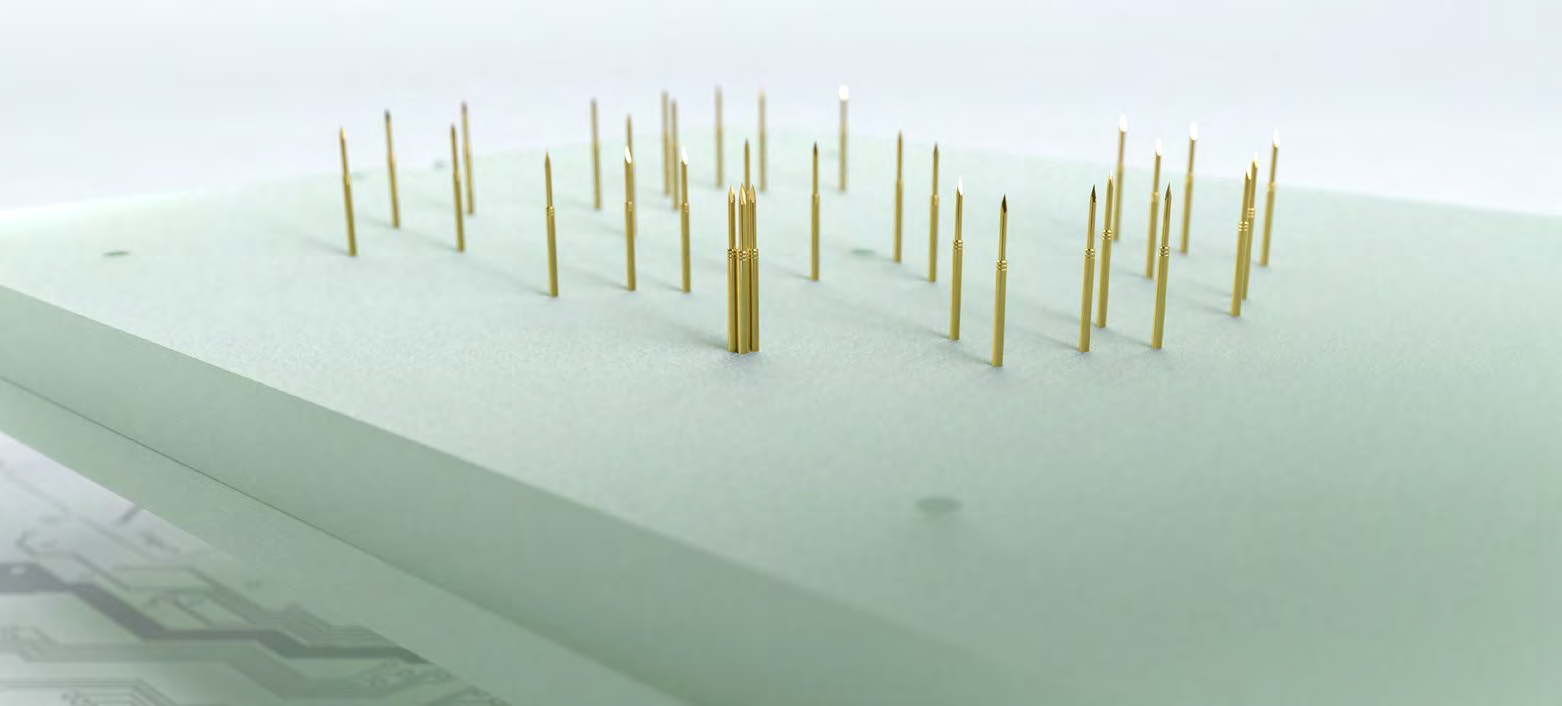

Deep cultivation in the martial arts world relies on solid internal skills. The testing probe may seem simple, but it is actually a finely crafted precision structure, with hidden secrets in each component, working together to create its "super strong combat power":

syringe needle:The part that directly contacts the test point is often made of wear-resistant and highly conductive materials, and is gold-plated to ensure good electrical contact and corrosion resistance.

Needle tube:Support and guide structure to maintain the positional accuracy of the needle during multiple tests.

Spring:Provide appropriate contact pressure to ensure stable signal connection while avoiding excessive pressure damage to the test points.

This integrated design enables the test probe to maintain high mechanical accuracy and electrical performance consistency even with extremely small diameters. Gold plating treatment not only improves conductivity, but also enhances antioxidant capacity, allowing the test probe to maintain stable signal transmission quality even during long-term use.

Although the testing probe is small, it is a key link in the testing system that affects overall accuracy and reliability. Its main functions can be summarized as follows:

1. Accurate positioning:Accurately align small test points on high-density circuit boards.

2. Stable connection:Maintain low impedance electrical contact during the testing process.

3. Signal fidelity:Ensure that the waveform is not distorted during the transmission of high-frequency and high-speed signals.

4. Durability test:Can withstand tens of thousands of repeated contacts and maintain performance.

In the testing world, the "practical achievements" of testing probes are spread across various fields, becoming an indispensable "key player" whose position cannot be replaced by anyone:

The guardian deity of consumer electronics mass production: In the mass production process of consumer electronics products such as mobile phones and computers, testing probes are the "core combat force" for quality control. During the motherboard testing phase, hundreds of probes form a "testing array" that accurately targets various testing points on the motherboard, while detecting core components such as CPU, memory, and RF modules to screen out "unqualified products" such as virtual soldering and soldering, ensuring that every factory equipment has stable performance. A probe can complete tens of thousands of tests, supporting a million level mass production scale, improving production efficiency and reducing costs. It is the "behind the scenes hero" of the consumer electronics industry.

Its function goes far beyond that. In industrial automation and medical equipment, test probes are reliable tentacles for precision control; In the field of automotive electronics and new energy, it rigorously verifies the reliability of battery management systems and electric drive components, safeguarding driving safety and energy efficiency.

At the forefront of high-end technology that challenges the limits, testing probes are indispensable "pioneers of exploration". In the semiconductor field, it can accurately contact the micrometer sized pins on the chip to complete critical electrical performance testing; In space exploration, special test probes are more capable of penetrating extreme environments, withstanding high temperatures and pressures, and transmitting crucial measured data to key systems such as rocket engines.

The testing industry is constantly evolving, with consumer electronics products evolving towards "miniaturization and high performance". New technologies such as 5G-A and Wi Fi 7 continue to emerge, placing higher demands on the "martial arts" of testing probes. In the future, testing probes will advance towards the direction of "smaller and more durable", continuously consolidating their "status in the market":

Smaller size:To adapt to the design of high-density motherboards, the needle tip and needle tube of the testing probe will be smaller, just like a martial arts expert practicing "bone shrinking skills", accurately operating in a narrower space to cope with more complex testing scenarios.

More durability:By optimizing the material, improving the coating process, and enhancing the fatigue strength of the spring, the service life of the testing probe will be further extended, and it can withstand higher frequency tests, just like the martial arts master practicing the "longevity skill", continuously providing stable support for mass production testing.

The testing probe, although small in size, is indeed an "invisible hero" in the field of technology, silently guarding product quality and technological progress. In the future world, this small testing probe will continue to improve and conquer a wider range of testing fields with stronger strength, writing its own "Jianghu legend".