Time:2025-07-18Reading:1225Second

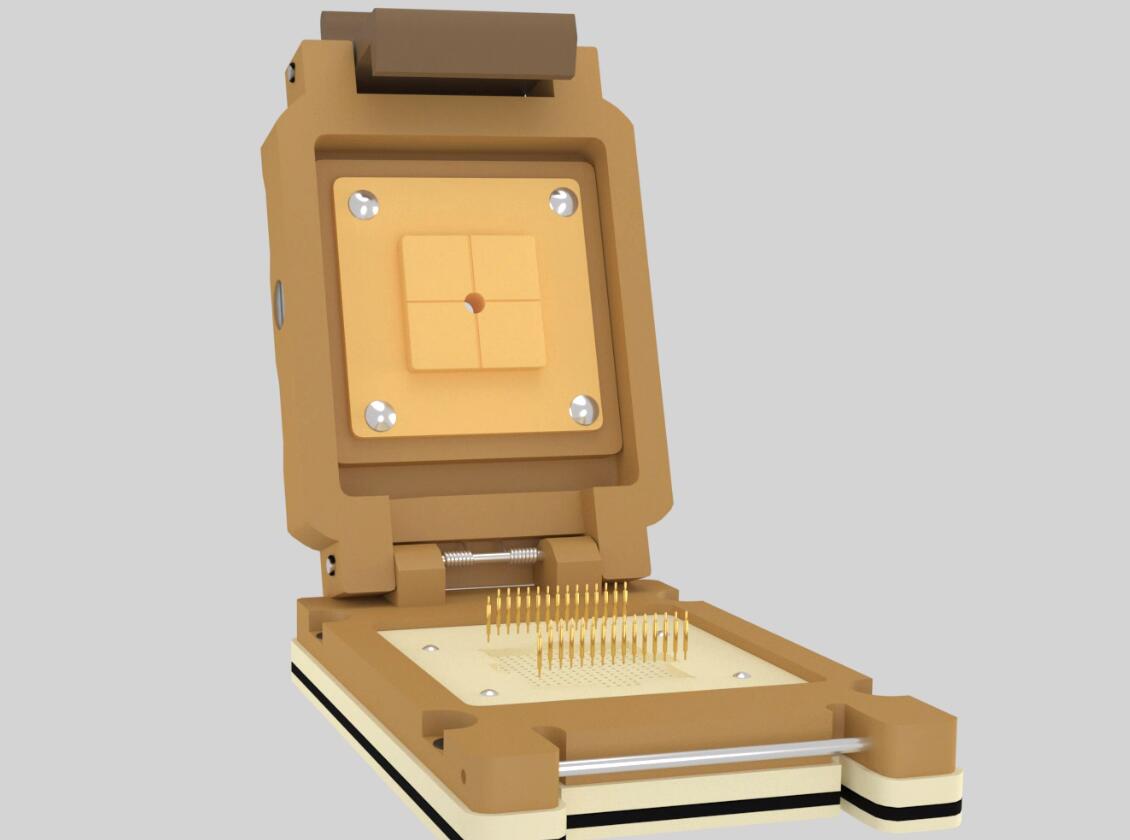

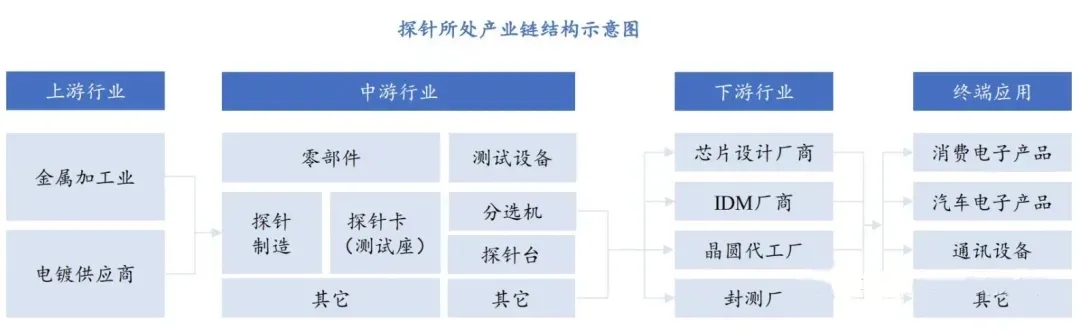

In the precision testing process of the semiconductor industry, test probes play an indispensable role. As a core component that connects chips/wafers with testing equipment, it plays an important role in signal transmission during critical processes such as chip design verification, wafer testing, and finished product testing, directly related to the quality control of semiconductor products.

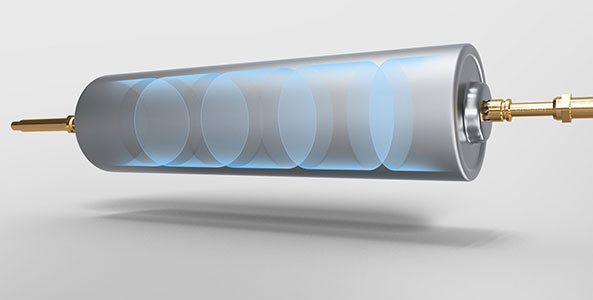

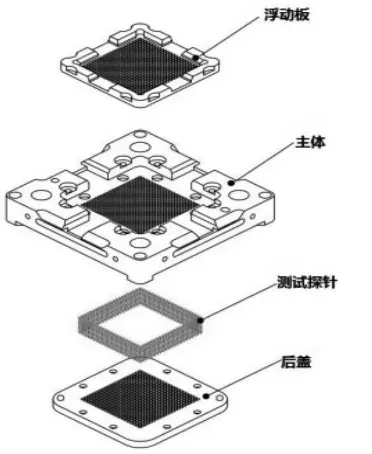

The probe is mainly composed of three basic components: the needle, the needle tube, and the spring, which are pre pressed by precision instrument riveting. Due to the extremely small size of semiconductor products, especially chips, the size of probes is required to reach the micrometer level, which requires a high level of manufacturing technology.

During wafer or chip testing, the function of probes is to achieve precise connection between wafer/chip pins or solder balls and the testing machine, thereby completing signal transmission and detecting performance indicators such as conductivity, current, functionality, and aging of the product. Probes with different purposes may have differences in appearance, but they all have precise spring structures inside. Moreover, the surface of the product is usually gold-plated, which gives it strong corrosion resistance, excellent electrical performance, stable working condition, and long-lasting service life.

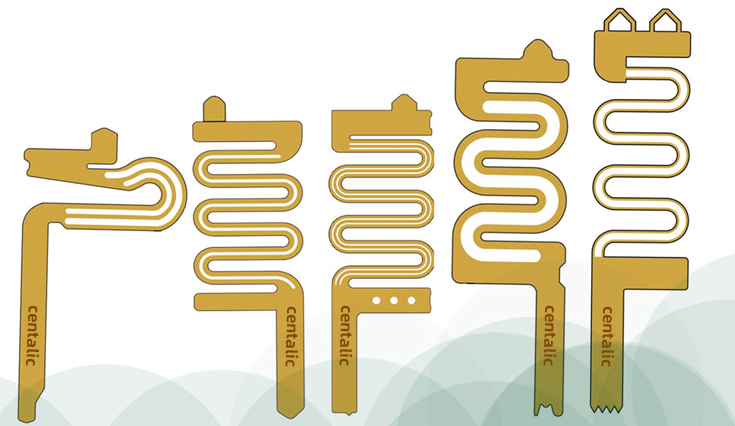

As a key component in semiconductor testing equipment, factors such as the structural design, material selection, and elasticity of the probe will affect its stability, refinement level, signal transmission accuracy, and thus affect the testing accuracy of the probe.

syringe needle:Directly contact the critical parts of the tested device.The selection of needle tip type will directly affect the testing effect. Needles are made of several materials such as brass, palladium alloy, beryllium copper, SK4, etc. Their hardness performance (brass<beryllium copper<palladium alloy<SK4), the higher the hardness, the more wear-resistant the needle.

Needle tube:Provide mechanical support and signal transmission channels. Internally equipped with springs, mainly made of materials such as phosphor copper tube, brass tube, white copper tube, etc.

Spring:Ensure stable contact elasticityThe main materials are stainless steel wire and piano wire.

Stainless steelIt is the preferred material for probe springs due to its corrosion resistance, high temperature resistance, and resistance to rusting;

piano wireStrong elasticity value, but prone to rusting due to moisture, so there is no specific requirement to generally not use piano steel wire springs

Coating:The probe surface is coated with nickel plating and gold plating. Nickel plating is more wear-resistant, while gold plating has the best electrical properties.

Due to the complex production process of semiconductor products, any process error can lead to a large number of product quality defects and have a significant impact on the performance of end use products. Therefore, testing is crucial for the production of semiconductor products, running through the entire process of semiconductor product design, manufacturing, packaging, and application.

Probes are important consumables required in semiconductor testing. They are used in conjunction with testing machines, sorting machines, and probe stations for design validation, wafer testing, and finished product testing to screen for product design and manufacturing defects. They play an important role in ensuring product yield, controlling costs, guiding chip design, and process improvement.

Centalic profitFocused on probe research and development production for over 40 years, with a complete "one-stop" production line. After the raw materials are received, each process step including turning, cleaning, heat treatment, electroplating, assembly, inspection and shipment is controlled by our company's self operated production line, with standardized production processes and strict control over delivery time and quality.