Time:2025-07-25Reading:895Second

In today's rapidly developing technology, chips have become the "brain" of the digital age. From smart phones to supercomputers, from smart appliances to autonomous vehicle, chips are everywhere. However, few people know that the birth of every qualified chip relies on a seemingly small but crucial component - the test probe.

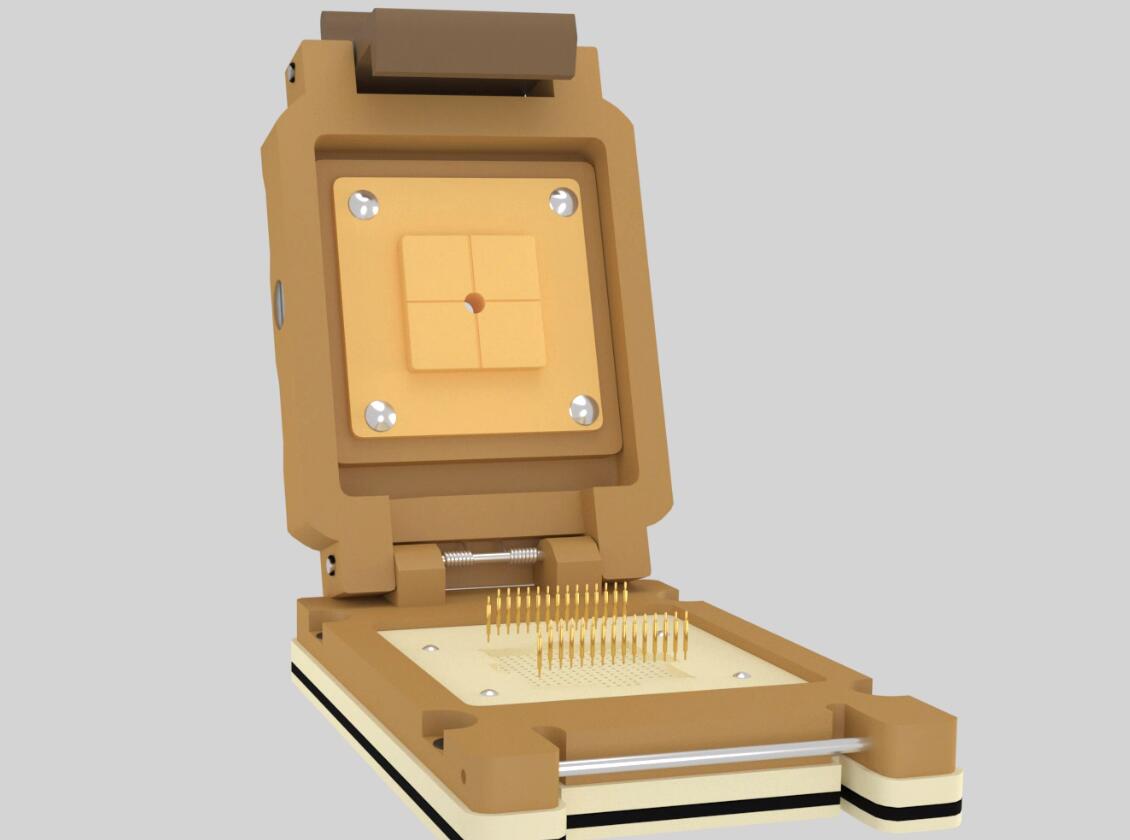

Chips must go through a strict testing process before mass production, and testing probes play a key role in it. Its working principle seems simple: using test probes to make precise contact with chip pads, transmitting test signals, and detecting various performance indicators of the chip. However, this process involves extremely high technical requirements:

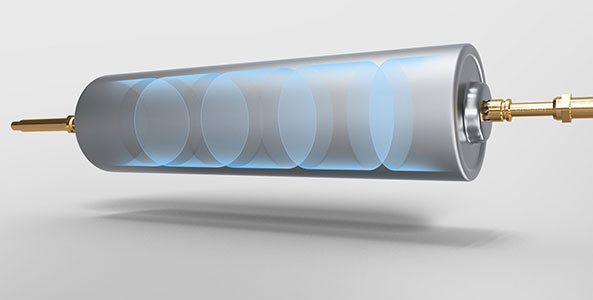

Wafer Testing (CP):Before chip cutting and packaging, thousands of probes on the probe card simultaneously contact the chips on the wafer for preliminary screening, effectively avoiding defective products from entering the subsequent high cost packaging process.

Final Test (FT):After the packaging is completed, the probe conducts a comprehensive functional verification of the chip again to ensure that the product fully meets the design specifications.

A reliable and stable testing probe is a key factor in ensuring chip yield, and its performance directly affects the quality and cost of the product.

Global ExplorationThe needle technology market is fiercely competitive and has long been dominated by companies from countries such as the United States, Japan, and South Korea. These companies rely onThe profound accumulation in the fields of precision manufacturing and materials science maintains a leading position in the market.

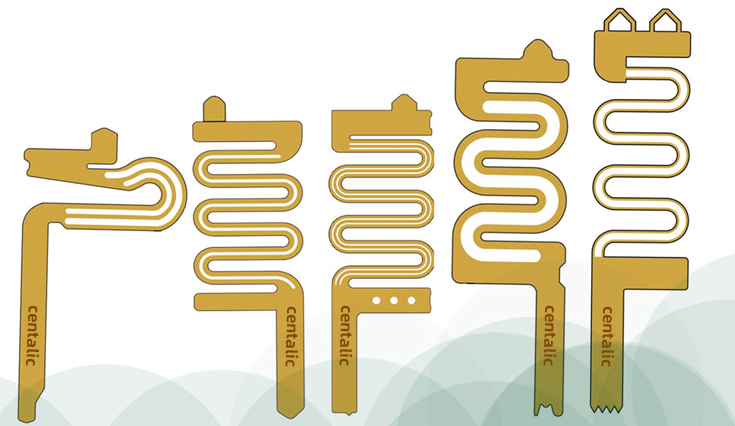

Centalic has been focusing on probe research and production for more than 40 years. It is a national high-tech enterprise with a "fully self operated large-scale" probe production line, specializing in the research and manufacturing of various testing probes. Provide one-stop probe testing solutions and customized probe services!

High density and small spacing testing requirements:As chip processes evolve towards 2nm and more advanced nodes, probe technology also faces new challenges.

High frequency testing capability:Meet the testing requirements of high-frequency application scenarios such as 5G/6G.

Despite their small size, test probes play an irreplaceable role in various aspects of chip manufacturing. It not only ensures the quality of chip products, but also promotes technological progress in the entire semiconductor industry.

Looking ahead to the future, with continuous technological innovation, testing probes will develop towards higher precision and stronger performance, providing more solid technical support for the digitalization process of humanity.