Time:2025-09-01Reading:895Second

In fields such as electronic testing, power transmission, and new energy equipment, high current needles are the core components for achieving current conduction and signal transmission. It is like a "current bridge" for equipment, which can withstand high loads, mechanical losses, and environmental erosion for a long time. However, many users often neglect detail management, resulting in poor probe contact, overheating and burning, and even causing "major problems" such as equipment shutdown.Centalic Today, let's have a systematic discussion with everyone: How to scientifically maintain high current needles for long-term use? At what time should we decisively replace it?

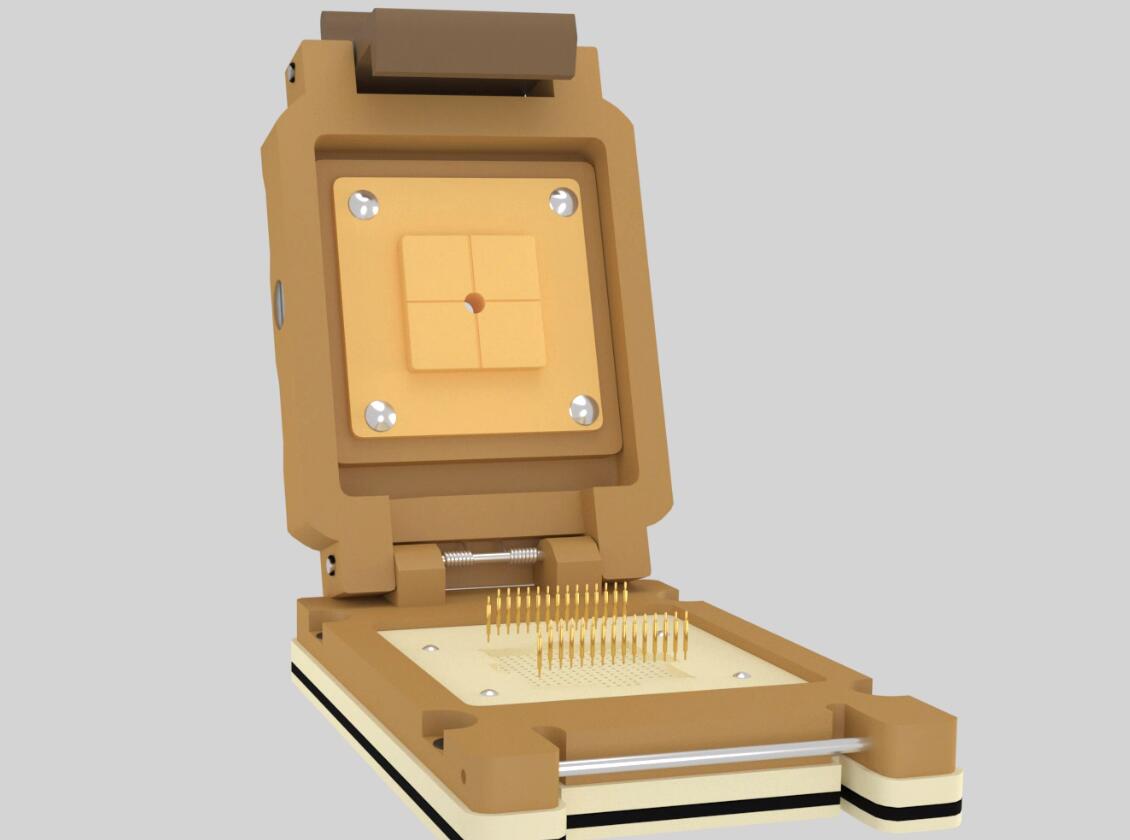

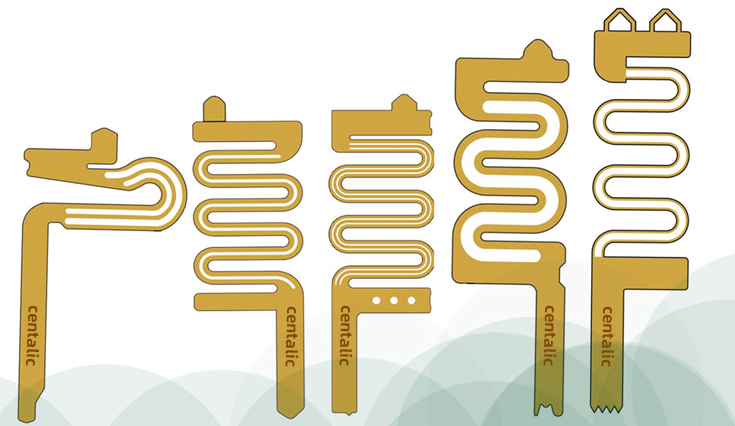

A high current needle is a test probe specifically designed to carry high currents, which can effectively transmit high currents during electronic testing. High current needles are mainly used in the field of online testing for high temperature and high current. For example, testing of photovoltaic and new energy batteries, which have the characteristics of high testing current and high testing temperature conditions. Another application is precise measurement, which requires the use of low resistance test probes, also known as low resistance probes.

The failure of high current probes is often not a sudden occurrence, but the result of long-term accumulation of "small problems". Proper maintenance of the following details can reduce wear and aging from the source.

1、 Contact interface: oxidation and wear“worst-hit area”

The contact interface between the needle of a high current probe and the measured object is the most prone to problems during long-term use. Continuous current flow will accelerate the oxidation of the contact surface, forming a high resistance oxide layer; Frequent plugging and unplugging can cause wear on the needle coating, making it more susceptible to corrosion after exposing the substrate material.

Focus: When the wear area of the coating exceeds 30%, replace the probe needle in a timely manner.

2、 Structural stress:springRegarding the needle body“Fatigue warning line”

Bullets inside the probespringResponsible for maintaining stable contact pressure, long-term exposure to thermal stress caused by high current, and mechanical impact during insertion and removal, which can easily lead to fatigue phenomena such as elastic attenuation and fracture; If the material strength of the needle body is insufficient, it may also undergo bending deformation due to repeated stress.

Focus: Regularly check the elasticity of the probe (which can be determined by measuring whether the contact pressure meets the standard), observe whether there are visible bends or cracks in the needle body, and pay special attention to the firmness of the connection between the needle and the needle tube.

3、 Heat dissipation efficiency: high temperature“hidden killer”

When a large current passes through, the probe itself generates Joule heat. If the heat dissipation is not timely, the temperature will continue to rise, accelerating material aging and even causing adjacent components to overheat. Dust and debris accumulation will further hinder heat dissipation, forming a vicious cycle.

Focus: Regularly clean the probe and surrounding dust and oil stains to ensure smooth heat dissipation channels;

4prohibit“Violent plugging and unplugging”:Protecting mechanical structures

When inserting and unplugging, it is necessary to maintain "vertical alignment": tilting insertion and unplugging can cause the probe tip and interface contacts to "wear off", which can lead to long-term deformation of the probe tip and wear of the coating.

Focus: Control the insertion and extraction force, and operate according to the "rated insertion and extraction force" indicated in the probe manual to avoid excessive force that may cause the internal spring of the probe to be misaligned, the needle tube to deform, or the interface to be damaged.

fiveLifetime threshold: number of insertions and removals“countdown timer”

Each high current probe has a design lifespan. After long-term high-frequency use, even if there is no obvious damage to the appearance, the wear of the internal structure may lead to a significant decrease in performance. Continuing to use beyond the lifespan will increase the probability of poor contact sharply.

Focus: Record the actual number of insertions and removals of the probe, and include it in the replacement plan in advance when it approaches 80% of the lifespan threshold; For probes of critical equipment, it is recommended to shorten the replacement cycle to avoid sudden failures.

The replacement of probes cannot be based on "feeling". The following three scenarios require decisive action:

1Must be replaced: Performance has expired

Frequent occurrence of poor contact (signal interruption, resistance jump), but there is still no solution after cleaning and adjustment.

The contact resistance exceeds the upper limit specified in the manual (e.g. a certain model requires ≤ 50m Ω, measured ≥ 100m Ω).

The needle is broken, bent, or the needle tube is cracked or deformed, and the expansion and contraction are completely stuck.

Black spots and burn marks appear on the surface, and the coating melts due to high temperature.

2Suggested replacement: The wear and tear have become apparent

The coating on the needle has peeled off by over 30%, exposing the underlying metal.

The tip of the needle is severely worn (rounded tip and flattened tip), affecting the contact area.

The spring experiences elastic attenuation (feels "soft collapse" when pressed) or rusting.

3Preventive replacement: planned according to frequency

High current probes have a clear "service life" and need to be planned in advance based on daily usage frequency.

The long-term stability of high current probes relies on precise control of daily operational details. Only by integrating detail management into daily life and implementing replacement plans can this "small component" continue to play a big role, building a solid defense line for stable operation in fields such as electronics, power, and new energy, and truly achieving the goal of "not letting small details cause big problems".