Time:2025-06-13Reading:837Second

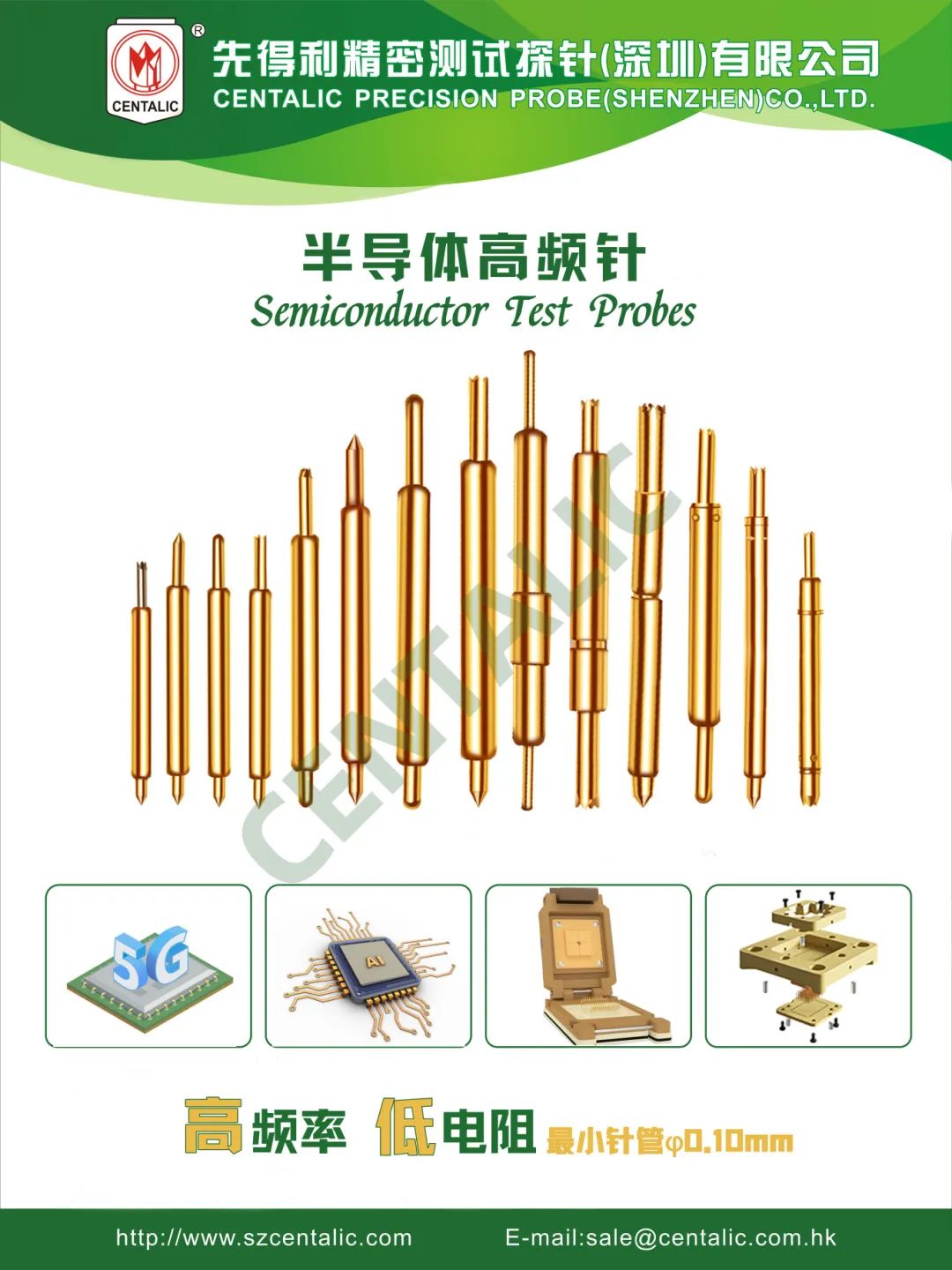

existOn June 11, 2025, Huawei made a stunning debut with its Pura 80 series smartphones, quickly becoming the focus of the tech industry. From exterior design to internal performance, this series of phones demonstrates Huawei's innovative strength, with many highlights that are eye-catching. Behind this series of outstanding performances, there is a 'behind the scenes hero' - the semiconductor high-frequency needle,It plays a crucial role in the manufacturing and testing of mobile phones.

Semiconductor high-frequency needles are mainly used for various communication power electronic components, semiconductor wafer testing, chip packaging testing, and other processes with extremely low contact resistance and ultra-high bandwidth, which can meet the testing requirements of 5-40G high-frequency signals.

At present, Centalic can process the minimum probe diameter: needle diameter: 0.06mm/needle tube diameter: 0.10mm.

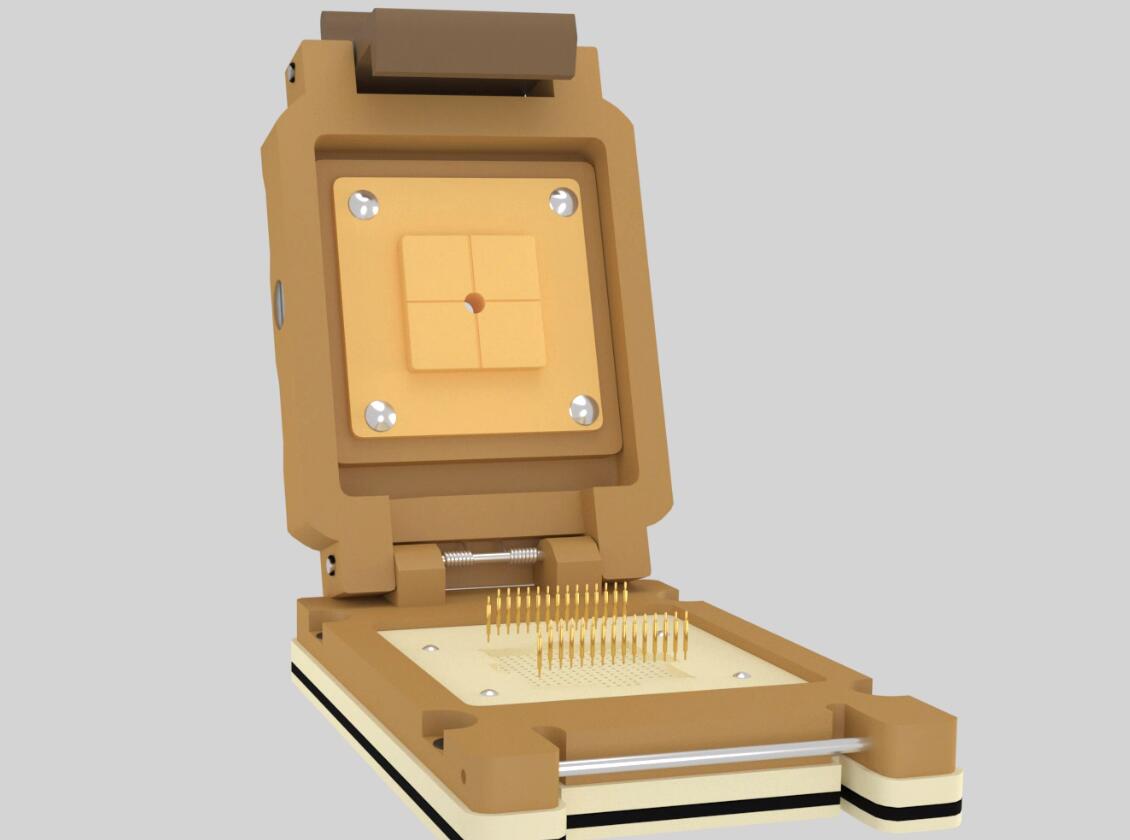

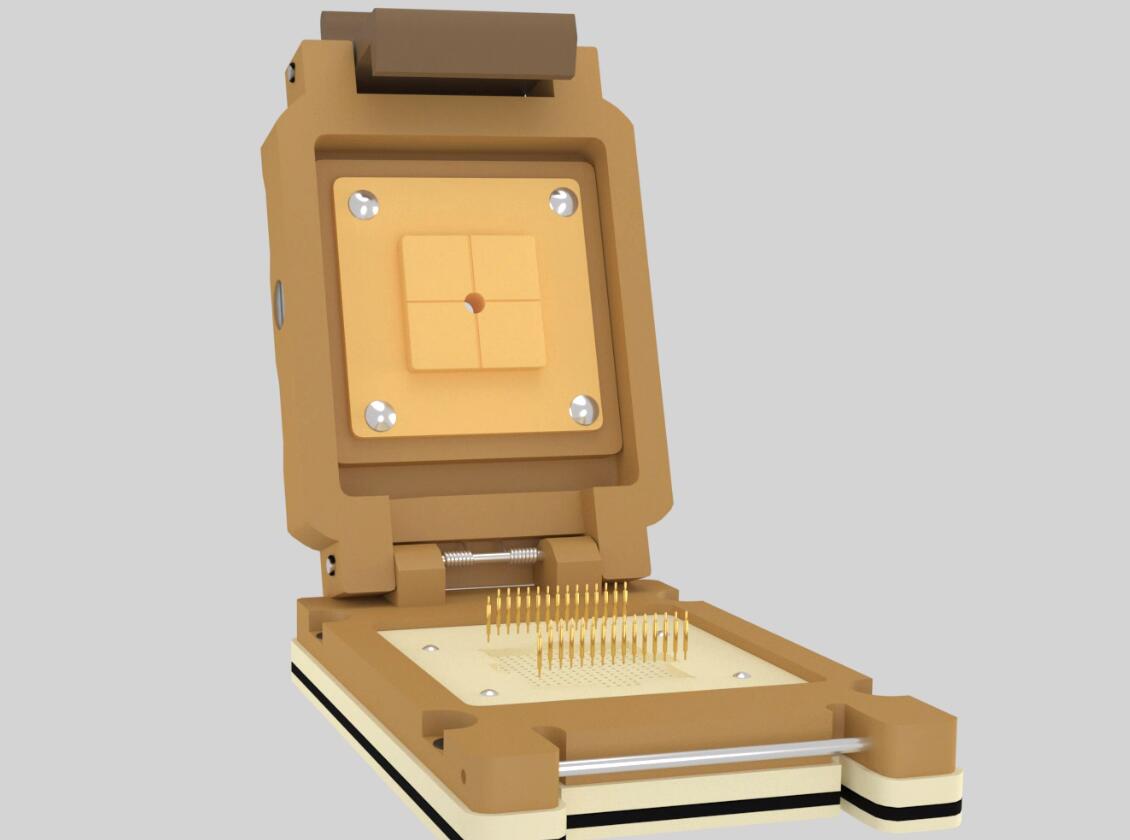

Chip testing

Semiconductor high-frequency needles play a crucial role in mobile phone chip testing. Mobile phone chips are the core components of smartphones, and their performance and quality directly affect the overall performance of the phone. By contacting the semiconductor high-frequency needle with the mobile phone chip, key parameters such as voltage, current, and frequency of the chip can be accurately detected, ensuring that the performance of the chip meets the design requirements. This step is crucial for ensuring the stability and reliability of mobile phone chips.

Screen and camera testing

Semiconductor high-frequency needles are also widely used for testing key components such as mobile phone screens and cameras. The quality of mobile phone screens directly affects the user's visual experience, and semiconductor high-frequency needles can accurately test parameters such as brightness, color, resolution, etc. of the screen to ensure optimal screen performance. For mobile phone cameras, semiconductor high-frequency needles can comprehensively detect key indicators such as pixels, color reproduction, and clarity, providing users with a clearer photography experience.

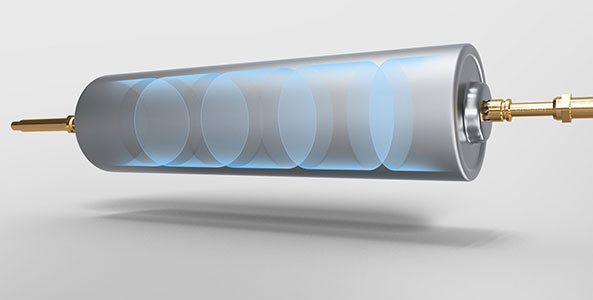

battery test

In addition, in battery testing, semiconductor high-frequency needles can accurately measure the voltage, current, and capacity of the battery, ensuring battery endurance and safety of use.

As a national high-tech company with over 40 years of "fully self operated and large-scale" probe production lines, Centalic focuses on the research, development, and manufacturing of various testing probesNew technology enterprisesIndustry. By adopting advanced material structures, lean coating treatments, and high-quality assembly processes, we provide customers with better testing probe products.