Time:2025-06-06Reading:1041Second

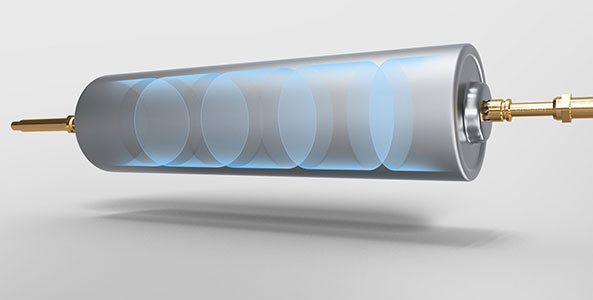

In modern electronic devices and industrial testing fields, high current needles play an irreplaceable role as a key connecting component. Whether it is battery testing for new energy vehicles, power system debugging, or current transmission for high-precision instruments, high current needles directly affect the safety, stability, and efficiency of the equipment. However, many people's understanding of it still remains at the surface level. This article will take you on a deep exploration of the "secrets" of high current needles from the perspectives of principles, applications, and advantages.

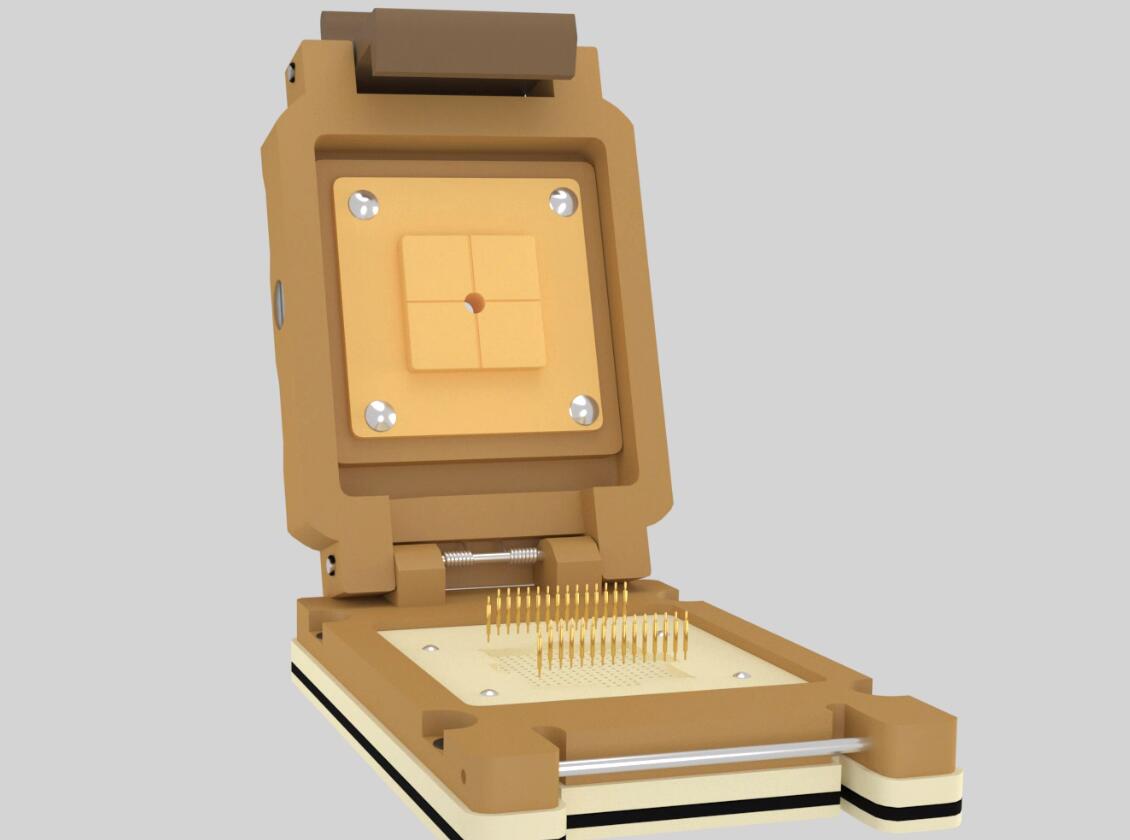

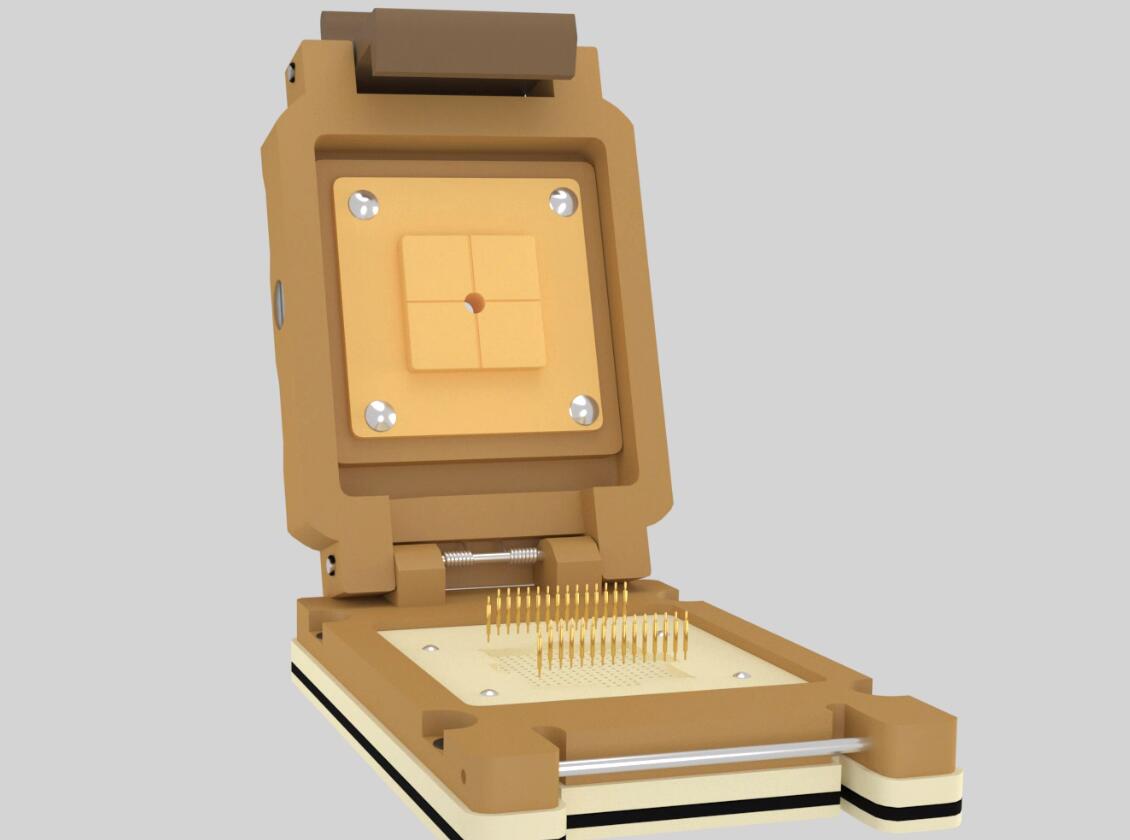

A high current needle is a test probe specifically designed to carry high currents, which can effectively transmit high currents during electronic testing. The characteristics of a high current needle are high testing currents and high testing conditions and temperatures. Mainly used in the field of online testing for high temperature and high current. Such as testing, functional testing, signal transmission, power supply, during production, and used as built-in contact components, as well as for precise testing.

Material conductivity

It depends on the conductor material here, such as common copper and aluminum wires, where copper has a conductivity at least 30% higher than aluminum. And when necessary, silver lines may also appear. In addition to the substance of the material, it also depends on the purity of the material. Taking copper as an example, the highest purity red copper has a much higher conductivity than the second grade brass.

Probe core area

That is to say, what we often refer to as "wire diameter", such as 2.5 square millimeters, 4 square millimeters, etc. commonly used in decoration, all refer to wire diameter. Just to emphasize here, it is not the cross-sectional area of the entire wire that determines the current carrying capacity, but the cross-sectional area of the conductor inside the wire. The thicker the line, the greater the current carrying capacity.

(1) In the field of new energy

Power battery testing:In the research and production process of electric vehicle power batteries, comprehensive testing of the battery's performance is required. High current probes are used to accurately measure parameters such as current and voltage during battery charging and discharging processes, providing data support for evaluating performance indicators such as battery capacity, cycle life, and charging and discharging efficiency. Through these test data, engineers can optimize battery design, improve battery performance and safety.

Charging station equipment:With the popularization of electric vehicles, the performance of charging piles is crucial as an important infrastructure. The high current needle is responsible for transmitting high-power electrical energy at the connection interface between the charging station and the electric vehicle. Ensuring stable current and efficient transmission is the key to achieving fast charging and ensuring the safety and reliability of the charging process.

(2) Manufacturing and Testing of Electronic Devices

Functional testing of electronic devices:For various electronic devices such as computers, mobile phones, servers, etc., functional testing is required during the research and production stages. High current probes can be used to test the operation of equipment under different current loads, evaluate the power management capability, heat dissipation performance, etc. of the equipment. For example, in the fast charging function test of mobile phones, a high current needle is used to simulate the high current input during the fast charging process, to detect the charging speed, heat generation, and stability of the charging circuit of the mobile phone battery.

(3) Industrial sector

Motor testing:In the production, manufacturing, and maintenance process of motors, it is necessary to test the performance of the motors. The high current probe is used to input high current into the motor winding and test parameters such as starting current, operating current, torque, etc. of the motor. Through these test data, it is possible to determine whether the quality of the motor is qualified and whether there are faults such as winding short circuits or open circuits.

Electrical equipment testing:Regular inspection and maintenance are crucial for various types of power equipment, such as transformers, switchgear, etc. High current probes can be used to detect the conductive connection parts of equipment, such as busbar connection points, cable joints, etc. By passing a high current, the heating situation of these parts under high current loads can be detected to determine whether their contact is good and whether there are problems such as looseness and oxidation. Timely detection and resolution of these issues can ensure the safe and stable operation of power equipment and avoid power accidents caused by poor contact.

High precision measurement performance:The high current needle has high-precision measurement performance, which can ensure the accurate transmission and reception of electrical signals in the battery system, providing reliable data support for the evaluation and optimization of battery performance.

Corrosion resistance and durability:The high current needle is made of corrosion-resistant materials and can withstand long-term use in high load working environments, ensuring the reliability and stability of the battery system.

Stable connectivity performance:A high current needle can provide higher current transmission capability, making the connector more stable when transmitting data and power, and reducing the risk of connection interruption.

Excellent adaptability and compatibility:The high current needle can be customized and produced according to different models and specifications of new energy batteries to meet the needs of different battery systems. Its compact size, high density, and lightweight also make it easier to adapt to various complex testing environments and application scenarios.

As a key component of high-power electrical systems, the performance of high current probes directly affects testing accuracy and system reliability. Centalic profitIt is a national high-tech enterprise with over 40 years of "fully self operated large-scale" probe production line, focusing on the research and development and manufacturing of various testing probes. Centalic continuously optimizes material processes and structural design to provide customers in fields such as new energy and power electronics with high current probe connection solutions ranging from standard products to customized ones. Meet the testing requirements of different application scenarios.