Time:2025-10-11Reading:554Second

On October 7th, Lei Jun announced that the first sales performance of Xiaomi 17 series far exceeded expectations, and the three major first sales rights will continue until October 31st. Previously, Lu Weibing revealed on October 2nd that the sales of this series of mobile phones have exceeded one million units. Official data shows that within just 5 minutes of its launch, the entire series broke the record for the first sales of domestic smartphones in the entire price range in 2025. Among them, the Pro Max single model set a new record for the first day sales and sales of domestic smartphones this year.

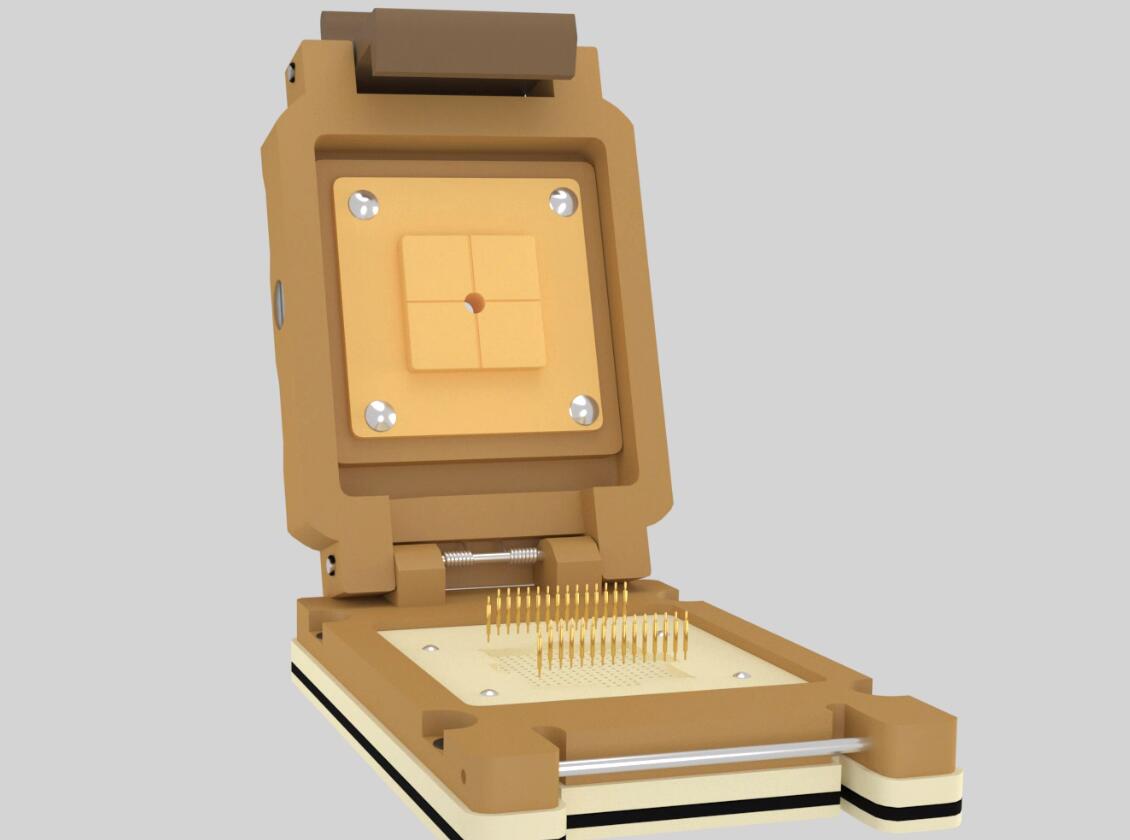

The back of market heat and user recognition is the solid investment of Xiaomi 17 in technology and quality control. In key stages such as chip testing and communication module verification, the semiconductor high-frequency needle serves as the core testing component, providing invisible but crucial support for the overall performance and reliability of the machine.

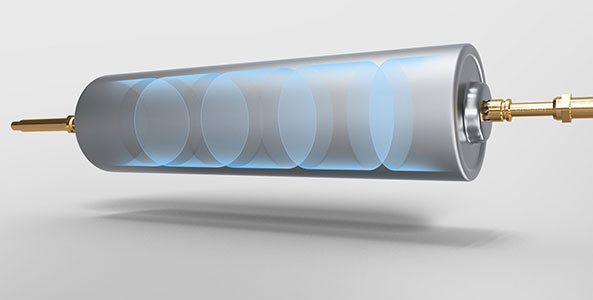

Semiconductor high-frequency needles are mainly used in various communication power electronic components, semiconductor wafer testing, chip packaging testing, and other processes. With extremely low contact resistance and ultra-high bandwidth, they can meet the testing requirements of 5-40G high-frequency signals.

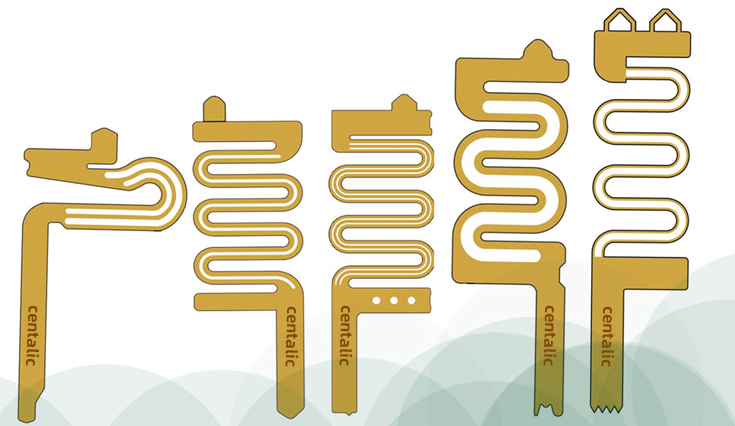

At present, Centalic can process the minimum probe diameter: needle diameter: 0.06mm/needle tube diameter: 0.10mm.

Before the Xiaomi 17's processor entered mass production, the semiconductor high-frequency needle undertook a crucial testing task. Through wafer testing and chip packaging testing, high-frequency needles can accurately detect various performance indicators of chips, ensuring that the chips meet design standards.

Guarantee of signal integrity

As a flagship phone, Xiaomi 17 supports high-speed communication standards such as 5G. During the testing process, the semiconductor high-frequency needle can verify the signal quality of the RF front-end and ensure that the performance of the communication module meets the standards. This is crucial for user experience and directly relates to the communication stability of mobile phones in actual use.

The key to consistency in mass production

Facing the sales target of millions, ensuring consistency in product quality has become a huge challenge. Semiconductor high-frequency needles help manufacturers screen qualified components through precise testing data, and control the overall quality of the machine from the source.

Although semiconductor high-frequency needles are only a small link in the industry chain, they play an indispensable role in the entire quality system. Its precise testing provides the most basic and important guarantee for the overall quality of the machine.

As a national high-tech enterprise with over 40 years of "fully self operated and large-scale" probe production lines, Centalic focuses on the research and manufacturing of various testing probes.Provide one-stop probe testing solutions and customized probe services!By adopting advanced material structures, lean coating treatments, and high-quality assembly processes, we provide customers with better testing probe products.