Time:2025-10-24Reading:810Second

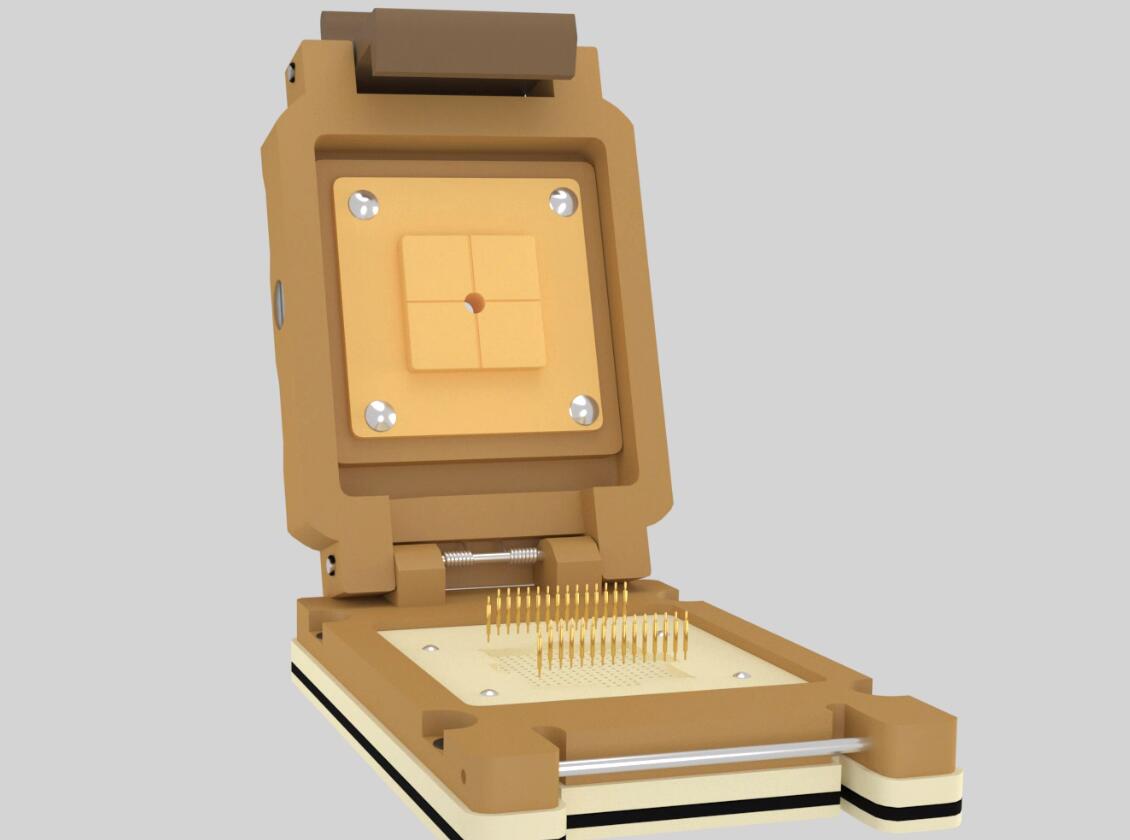

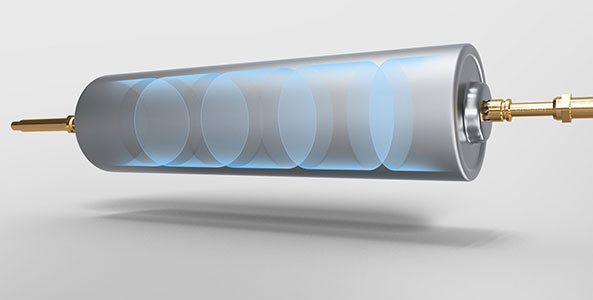

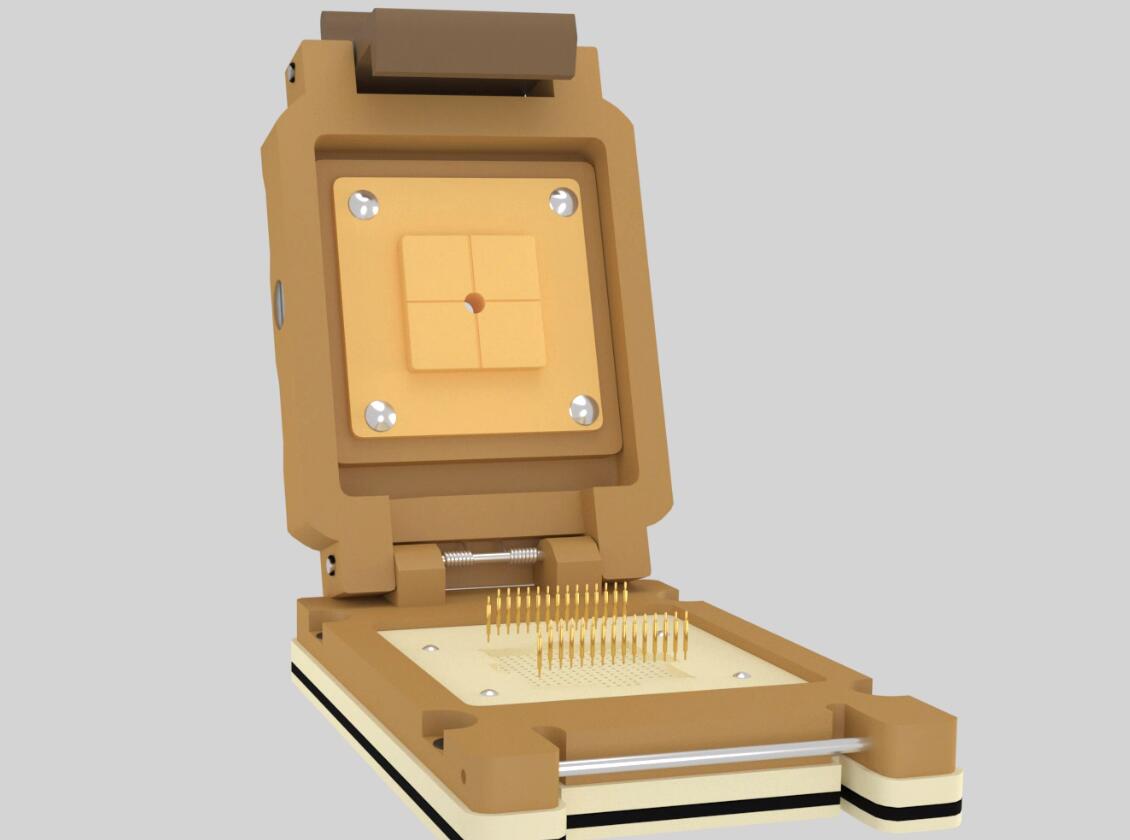

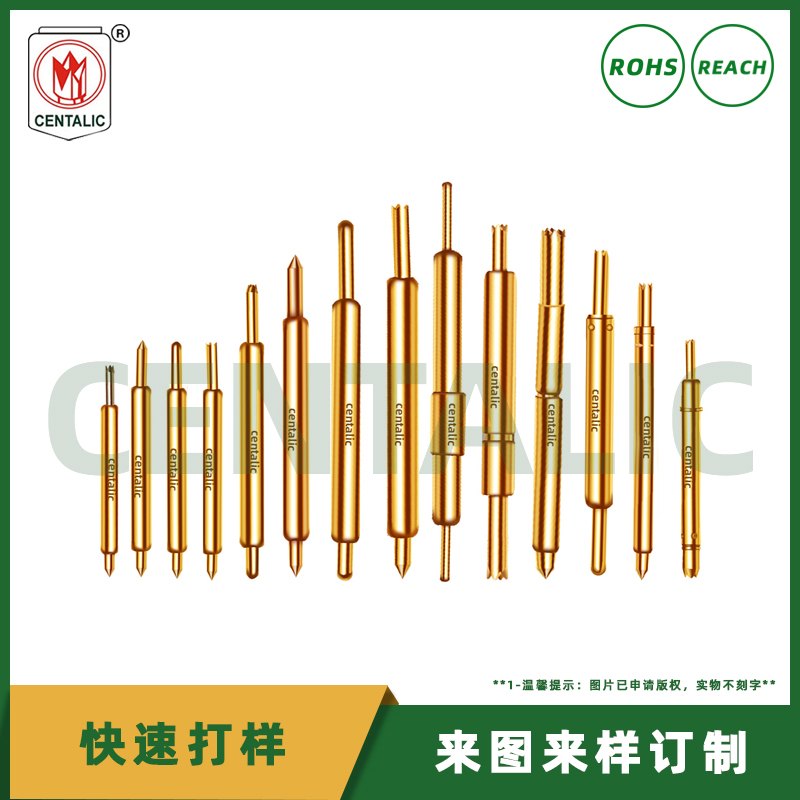

Before discussing prices, we first need to understand what a "probe" is. A probe is a miniature conductive component used for electronic testing, which transmits electrical signals through precise contact with the testing point to determine the performance of the product.

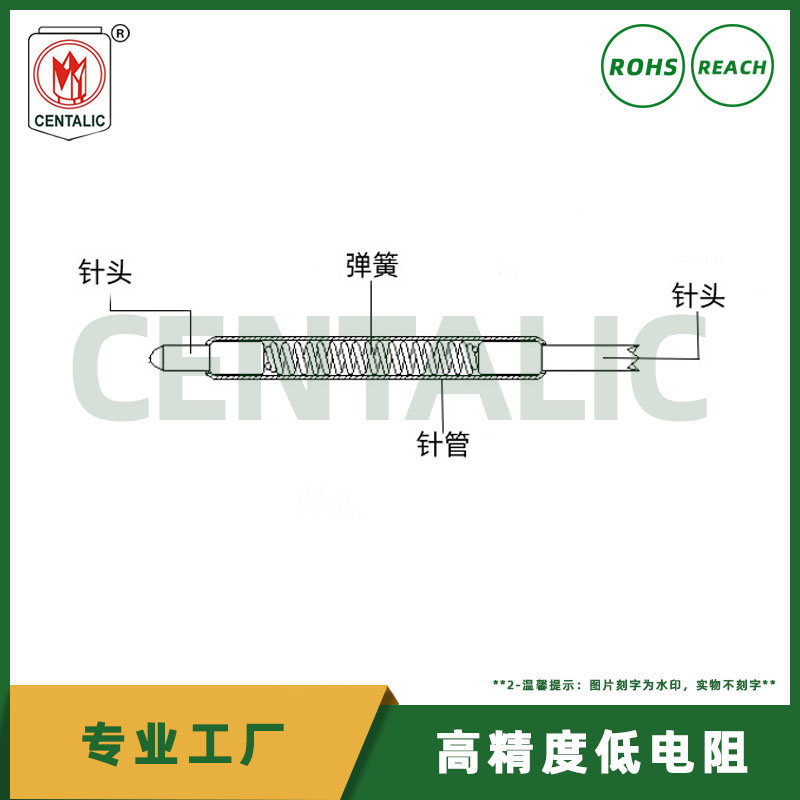

A probe typically consists of three parts:

syringe needle:Directly contact the critical parts of the tested device. Needles are made of several materials such as brass, palladium alloy, beryllium copper, SK4, etc. Their hardness performance (brass<beryllium copper<palladium alloy<SK4), the higher the hardness, the more wear-resistant the needle.

Needle tube:Provide mechanical support and signal transmission channels. There are materials such as phosphor copper tube, brass tube, white copper tube, alloy tube, nickel tube, etc.

Spring:Ensure stable contact elasticity. There are stainless steel wires, piano wires, and non-magnetic wires.

Coating:The probe surface is plated with nickel, rhodium, and gold. Nickel plating and rhodium plating are more wear-resistant, while gold plating has the best electrical properties.

1. The gold plating of probes is to prevent oxidation and rusting of the test probe body, as the oxide layer or rust spots generated after oxidation will increase the resistance of the probe, thereby reducing its stability during testing and affecting its testing performance.

2. The gold plating layer has good ductility, easy polishing, high temperature resistance, and excellent resistance to discoloration. And the thicker the gold plating layer of the probe, the better the electronic performance, wear resistance, and service life of the product.

3. In addition, the gold plating layer has the characteristics of low contact resistance, easy soldering, good conductivity, and strong corrosion resistance, making it widely used in precision instruments, integrated circuits, and other fields.

We know that gold plating literally refers to plating gold, but in fact, what we mean by gold plating is not just plating the probe with gold. Before gold plating, we will first coat it with a layer of nickel. Nickel plating has high toughness and chemical stability. The cost of nickel plating is lower than that of gold plating, and nickel plating can also achieve antioxidant and wear-resistant effects. However, its conductivity is not as good as gold plating. Reducing resistance and good conductivity are very important in the probe industry, so gold plating is used more frequently.

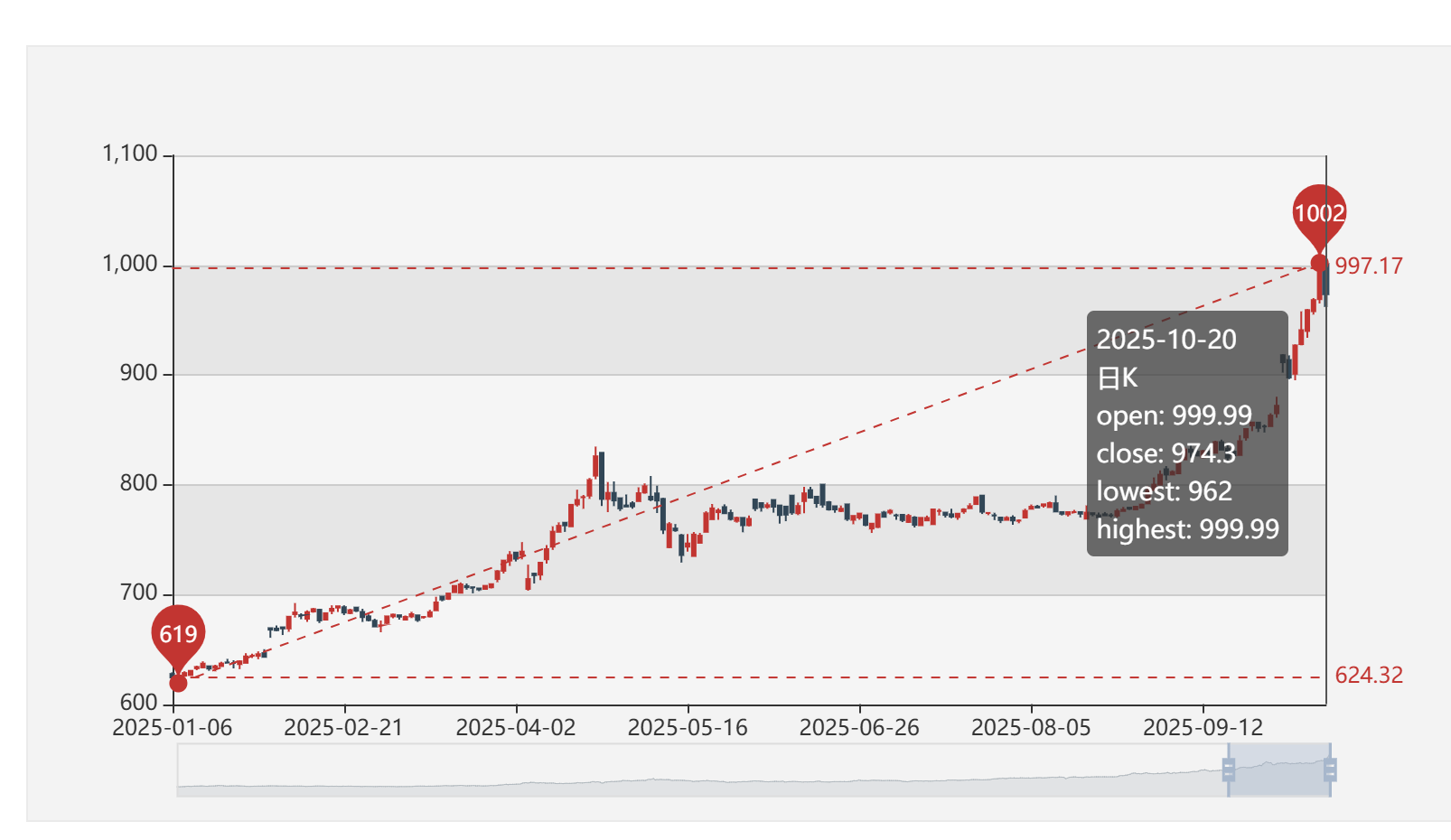

Sudden increase in raw material costs:The price of gold salts (such as potassium ferrocyanide) required for electroplating is directly linked to the international gold price. The rise in gold prices means that the cost of purchasing electroplating raw materials for probe manufacturers has significantly increased.

Supply chain cost transmission:Gold salt suppliers → electroplating factories → probe manufacturers, the pressure of gold prices is transmitted step by step along the industry chain, ultimately reflected in the ex factory prices of probes.

High end products have a greater impact:For higher demand application scenarios such as high-speed and high-frequency testing, thicker gold plating layers or the use of alloys with higher gold content may be required, as these probes are more sensitive to fluctuations in gold prices.

From this, it can be seen that the linkage between the rise in gold prices and probe prices is not a simple market coincidence, but a typical case of cost transmission in the global precision manufacturing system. It clearly reveals that in today's closely interconnected industrial ecosystem, the pricing fluctuations of international commodities will have a precise impact on the supply chain, ultimately reflected in the cost of a highly specialized industrial component.

The next time we hear that the gold price has hit a new high, we may have a deeper understanding: it is not only the ever-changing world of wealth, but also a silent transformation of precision manufacturing and testing costs, from the smartphones in our hands to the artificial intelligence chips driving the technological revolution. The value of gold is deeply embedded in the context of modern technology in an unexpected way.