Time:2025-11-29Reading:920Second

The unprecedented "three chip" strategy of Huawei Mate80 series hides a profound understanding of the laws of semiconductor manufacturing.

The basic version is equipped with the Kirin 9020 chip, which achieves a balance of "high yield and low cost" through mature manufacturing processes, providing space for a starting price of 4699 yuan;

As the absolute protagonist, the Kirin 9030, with its 2.75GHz ultra large core frequency and Mailoon935 GPU, has achieved a breakthrough in domestic technology in leakage control and voltage management;

Exclusive to ProMax modelskylin9030Pro, It is achieved through the performance upgrade of "wafer core area special selection" to ensure stability in high load scenarios.The precise division of these three-level chips is essentially a refined utilization of "manufacturing differences" - and the first hurdle in discovering these differences is the semiconductor probe.

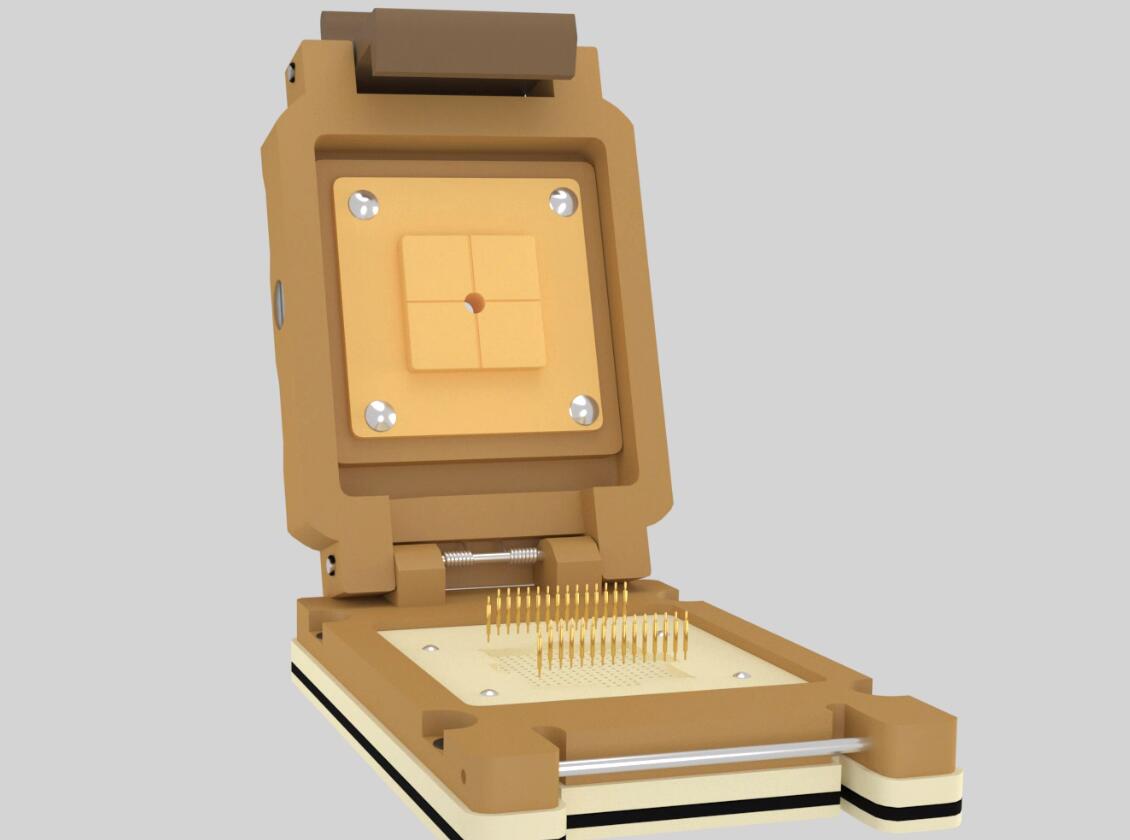

In the journey of Kirin chips from wafer to finished product, test needles play an irreplaceable role as "quality gatekeepers". To understand its importance, one must first understand its precise structure.

1. Precise structure of probe

Semiconductor probe is a high-end precision electronic component, also known as a "dual head test probe". Structurally, it is generally formed by three basic components: a needle, a needle tube, and a spring, which are pre pressed and riveted by precision instruments. According to the structure, it can be divided into series such as double head single action probe and double head double action probe. Common types of inner needle heads include B, J, J1, U, U1, etc. Due to the extremely small size of semiconductor products, especially chips, the size of probes needs to reach the micrometer level.

2. Probe function: precise touch and signal transmission

The core function of testing probes is to physically connect with the contact points of the chip through tiny needles after the chip manufacturing is completed, transmit testing signals to the inside of the chip, and read feedback data. This process not only verifies whether the chip functions properly, but also detects potential manufacturing defects. It can be said that every successfully manufactured chip relies on tens of thousands of "precise touches" from testing probes.

To support this' precise touch ', it requires the accumulation of probe structures and processes. As a national high-tech enterprise with over 40 years of "fully self operated and large-scale" probe production lines, Centalic focuses on the research and manufacturing of various testing probes. By carefully selecting high-quality materials, lean coating treatment, and precision assembly processes, this type of testing probe can process a minimum diameter of 0.06mm/0.10mm for the needle tip.

3. Three key applications on the Mate80 chip

For the Mate80 series, the detection of the test needle directly determines the performance grading and cost control of the final product:

Yield screening:The high yield of Kirin 9020 is due to the early screening of the testing needle, which can quickly remove grains with excessive leakage and circuit abnormalities, avoiding subsequent ineffective packaging costs.

Performance grading:The difference between 9030 and 9030Pro relies on the precise capture of the chip's power consumption and signal stability under high load by the test needle over a wide temperature range. The "potential stocks" with excellent performance are marked as 9030Pro, used for high-end models.

Process validation:The high-frequency breakthrough of Kirin 9030 is driven by a "stress test" aimed at testing domestic new processes, which verifies the reliability of transistor leakage control technology through simulating extreme scenarios.

With the advancement of chip processes below 3nm and the popularization of 3D packaging technology, test needle technology is facing the challenge of "three super":Ultra dense spacing, ultra-high frequency, and ultra long lifespanThis is not only a problem for probe manufacturers, but also requires deep linkage with the chip design process. For Huawei, which aims to compete at the top, mastering and leading this sophisticated testing language will be a must-have for whether its future flagship can continue to lead.